Common Materials Used in Car Wire Harnesses

Car wire harnesses use a range of materials, including copper, aluminum, PVC, XLPE, Teflon, nylon, polyester, PE, PP, PA6/66, brass, bronze, rubber, vinyl, electrical tape, and woven string.

Importance and Role in Material Selection | |

|---|---|

Electrical Conductivity | Copper is dominant due to excellent conductivity; aluminum requires larger cross-sections due to lower conductivity. |

Flexibility | Copper offers better flexibility and corrosion resistance, aiding assembly and reliability. |

Heat Resistance | Essential for high-temperature environments; copper generally performs better. |

Durability | Copper is preferred for reliability and resistance to environmental factors; aluminum needs coatings and special processing. |

Cost | Aluminum is gaining traction for cost-effectiveness and weight savings, but requires additional engineering. |

Application Variance | Luxury/performance vehicles prioritize conductivity, flexibility, heat resistance; economy/commercial vehicles emphasize cost and weight savings. |

Manufacturers select these materials for their conductivity, flexibility, heat resistance, durability, and cost. Copper stands out for reliability, while aluminum helps reduce weight and cost in car wire harnesses.

Key Takeaways

Copper is the most common conductor in car wire harnesses because it offers excellent conductivity, flexibility, and heat resistance, ensuring reliable performance.

Aluminum provides a lighter and cheaper alternative to copper but requires thicker wires and special coatings to prevent corrosion and maintain strength.

Insulation materials like PVC, XLPE, Teflon, and silicone protect wires from heat, chemicals, and damage, with each suited for different temperature and environmental needs.

Protective sleeves such as nylon and polyester shield wires from abrasion and moisture, while brass and bronze terminals ensure strong, corrosion-resistant connections.

Choosing the right materials depends on balancing performance, cost, and the vehicle’s environment to keep wire harnesses safe, durable, and efficient.

Conductors

Car wire harnesses rely on several metals to carry electricity safely and efficiently. Each metal offers unique strengths and weaknesses. The following sections explain the main conductor materials used in automotive wiring.

Copper

Copper remains the most popular conductor in car wire harnesses. It provides excellent electrical conductivity, second only to silver. Copper wires carry current with very little loss, which helps keep electrical systems efficient. This metal also resists corrosion well, so it lasts a long time even in harsh automotive environments.

Copper stands out for its flexibility and high mechanical strength. Installers can bend and route copper wires through tight spaces without breaking them. The metal’s high melting point allows it to handle heat from engines and electrical loads. Copper’s ductility means it can stretch without snapping, which is important during installation and use.

Tip: Copper wiring allows manufacturers to use thinner wires without losing strength or reliability.

However, copper costs more than other metals like aluminum. It also weighs more, which can affect fuel efficiency in vehicles. Copper wires can generate electromagnetic interference and do not handle electrical surges as well as some alternatives.

Excellent electrical conductivity

High heat resistance

Great flexibility and ductility

Strong corrosion resistance

Disadvantages of copper:

Higher cost and weight

Poor surge tolerance

Can cause electromagnetic interference

Mechanical and Flexibility Comparison Table:

Material Type | Mechanical Strength Characteristics | Flexibility Characteristics | Automotive Wire Harness Application Notes |

|---|---|---|---|

Pure Copper | High electrical conductivity, good tensile strength | High flexibility and reliability | Dominant conductor due to balance of conductivity, flexibility, and reliability |

Beryllium Copper Alloy | High strength, hardness, fatigue resistance; can be heat-treated | Excellent elasticity and form retention under repeated flexing | Used in demanding environments requiring mechanical durability and safety (e.g., aerospace, automotive wiring harnesses) |

Copper-Clad Aluminum | Higher tensile strength than pure aluminum; composite structure | Good flexibility due to copper cladding | Lightweight, cost-effective alternative with improved conductivity and mechanical strength over aluminum; used in automotive wiring |

Copper-Clad Steel | High mechanical strength and durability from steel core | Available in soft (annealed) or hard-drawn tempers | Used where strength and theft resistance are important; suitable for grounding and automotive wiring requiring durability |

Copper-Nickel Alloys | Corrosion-resistant, strong, ductile | Not explicitly detailed | Mentioned as corrosion-resistant alloys used in harsh environments, including automotive contexts |

Aluminum

Aluminum serves as a lighter and less expensive alternative to copper. It costs much less per kilogram, which helps reduce the overall price of car wire harnesses. Aluminum also weighs less, making it useful in vehicles where weight savings matter.

Aluminum does not conduct electricity as well as copper. To carry the same amount of current, aluminum wires must be thicker. This metal also has lower fatigue resistance, so it can break more easily if bent repeatedly. Aluminum expands more with heat, which can loosen connections over time.

Aluminum is more prone to corrosion, especially when exposed to moisture and road salts. Manufacturers often coat aluminum wires or use special connectors to prevent corrosion.

Metal | Scrap Price (USD/lb) | Price per kg (USD) Approx. |

|---|---|---|

#1 Bare Bright Copper Wire | $3.75 | $8.27 |

Aluminum 6061 | $0.52 | $1.15 |

Aluminum Thermo-Pane/Break | $0.35 | $0.77 |

Wiring Harness Scrap | $1.40 | $3.09 |

Note: Aluminum wiring helps reduce vehicle weight and cost, but it requires careful engineering to avoid problems with strength and corrosion.

Gold and Nickel

Gold and nickel do not serve as main conductors in car wire harnesses. Instead, manufacturers use them to improve the performance and durability of connectors and contacts.

Gold provides outstanding corrosion resistance. It does not tarnish or degrade, even in harsh automotive environments. Gold plating on connectors ensures stable current flow and reliable signal transmission. Gold also offers high ductility, making it suitable for flexible connections and springs. Its non-magnetic nature helps reduce electromagnetic interference.

Nickel often acts as a base layer under gold plating. It adds structural support and acts as a barrier to prevent gold from diffusing into other metals. Nickel plating improves wear resistance and corrosion protection. Electrolytic nickel works well for spring contacts and crimps, while electroless nickel provides a uniform coating and better hardness.

Typical Uses and Benefits Table:

Metal | Typical Use in Car Wire Harnesses | Benefits Provided |

|---|---|---|

Gold | Plating on connectors and contacts | – Superior corrosion resistance, preventing oxidation and degradation in harsh environments |

– High electrical conductivity ensuring stable current flow and reliable signal transmission | ||

– Enhanced durability, especially when alloyed as hard gold, supporting repeated connection cycles | ||

– High ductility suitable for flexible connections and springs | ||

– Excellent solderability for reliable joints | ||

– Non-magnetic properties reducing electromagnetic interference | ||

Nickel | Underplate/base layer beneath gold plating | – Provides structural support and diffusion barrier for gold plating |

Electrolytic nickel used for spring contacts, crimps | – Improves wear resistance and corrosion protection | |

– High melting point (>2000°F) suitable for high-temperature applications | ||

Electroless nickel plating | – Uniform coating thickness without dimensional impact | |

– Improved hardness and lubricity compared to electrolytic nickel | ||

– Non-magnetic (high phosphorus types) but lower melting point (~1500°F), less suitable for extreme heat | ||

– Less ductile than electrolytic nickel, not recommended for crimp applications |

Iron (Steel)

Iron, usually in the form of steel, does not serve as a primary conductor in car wire harnesses. Instead, manufacturers use it for reinforcement and grounding. Steel offers high mechanical strength and durability, making it suitable for areas that need extra protection or theft resistance.

Iron and steel are more prone to corrosion than copper or gold. They require coatings or special treatments to last in automotive environments. Steel’s strength makes it useful for grounding wires and for harnesses that need to resist physical damage.

Note: Gold offers the best corrosion resistance, followed by copper and nickel. Aluminum and iron are more likely to corrode, especially when exposed to moisture.

Insulation

Car wire harnesses need strong insulation to protect wires from heat, chemicals, and physical damage. The most common insulation materials include PVC, XLPE, Teflon, and silicone. Each material offers unique benefits for different automotive environments.

PVC

PVC, or polyvinyl chloride, is the most widely used insulation in car wire harnesses. It provides excellent electrical insulation and flexibility. PVC resists oils, chemicals, abrasion, and temperature changes. These qualities help wires perform well in harsh automotive conditions. Flexible PVC makes it easy to route wires through tight spaces. The material also offers flame retardancy and moisture resistance, which improve safety and lifespan. Manufacturers choose PVC because it is cost-effective and can be tailored with additives for extra protection.

Note: PVC insulation works best in environments where temperatures stay below 105°C. It is not ideal for high-temperature areas like engine bays.

XLPE

XLPE stands for cross-linked polyethylene. This material handles higher temperatures and mechanical stress better than PVC. XLPE insulation can withstand continuous temperatures up to 90°C and short bursts up to 130°C. Its cross-linked structure gives it high tensile strength and impact resistance. XLPE also resists acids, oils, and solvents, making it suitable for tough automotive settings. The material’s low thermal conductivity helps reduce heat loss. XLPE is non-toxic and environmentally friendly, which makes it a good choice for modern vehicles.

Key Properties of XLPE Insulation:

Withstands high temperatures (up to 130°C short-term)

Strong resistance to chemicals and abrasion

Maintains shape and durability under stress

Used in battery cables and engine wiring

Teflon

Teflon, also known as PTFE, is a high-performance insulation material. It provides excellent electrical insulation and does not conduct electricity. Teflon resists chemicals, UV rays, and high temperatures up to 200°C. Its low-friction surface reduces wear and makes installation easier. Teflon insulation stays flexible, even in cold or hot conditions. This flexibility helps wires bend without cracking. Teflon is common in engine compartments, brake sensors, heated seats, and electric vehicle wiring. It protects wires in places exposed to heat, chemicals, and vibration.

Teflon Insulation Advantages:

Outstanding chemical and heat resistance

Good flexibility for complex harnesses

Long-lasting protection against abrasion and moisture

Silicone

Silicone insulation stands out for its extreme flexibility and wide temperature range. It operates from -80°C to 180°C, making it suitable for both cold and hot environments. Silicone resists flames, passing strict flame tests, and does not melt quickly in fire. The material also resists gas, oil, ozone, and UV rays. Silicone keeps its shape under pressure and handles mechanical stress well. Automotive engineers use silicone insulation in areas with high vibration or where wires need to bend often. It is common in engine bays and other places with extreme temperatures.

Comparison Table: Insulation Materials in Car Wire Harnesses

Material | Temperature Range | Flexibility | Environmental Durability | Key Uses |

|---|---|---|---|---|

PVC | -20°C to 105°C | Good | Good, but halogen content raises disposal concerns | General wiring, cost-sensitive applications |

XLPE | Up to 130°C (short-term) | Moderate | Excellent, halogen-free | Engine wiring, battery cables |

Teflon (PTFE) | -60°C to 200°C | Good | Excellent chemical and heat resistance | Engine compartments, sensors, EVs |

Silicone | -80°C to 180°C | Excellent | Good, especially for high-vibration areas | Engine bays, high-flex harnesses |

Tip: Modern vehicles often use 105°C rated insulation for most wiring. Engine bays and high-heat areas require materials like XLPE, Teflon, or silicone for extra protection.

Protection

Protective sleeves and coverings play a vital role in car wire harnesses. These materials shield wires from abrasion, heat, and harsh conditions. The most common options include nylon, polyester, polyethylene (PE), polypropylene (PP), and polyamide (PA6/66).

Nylon

Nylon braided sleeving stands out for its light weight and flexibility. Installers find it easy to fit nylon over cables of different shapes and sizes. This material offers strong abrasion resistance and repels moisture, which helps prevent damage from wear and water. Nylon works well for protecting irregularly shaped wire bundles. However, nylon does not perform well at high temperatures and has limited resistance to chemicals, corrosion, and UV rays. For this reason, nylon sleeves are not suitable for engine compartments or areas exposed to automotive fluids.

Tip: Nylon is the most common choice for braided harness coverings in cars because it is light and flexible, but it should not be used where high heat or chemicals are present.

Polyester

Polyester sleeves and tapes provide high strength and excellent temperature resistance. Polyester can handle temperatures from -40°C up to 150°C, making it suitable for engine compartments. This material resists oil and corrosive substances, which helps extend the lifespan of wire harnesses. Polyester also stands up well to wear and aging. Its flexibility allows it to wrap tightly around wires, and the adhesive used with polyester tape sticks well to wire insulation. Due to its higher cost, manufacturers often use polyester in areas where heat and oil resistance are most important.

Property | Description / Typical Use |

|---|---|

High Strength | Strong tear resistance, made from polyacetate cloth base |

Temperature Resistance | -40°C to 150°C, suitable for engine compartments |

Oil and Corrosion Resistance | Resists oil and corrosive substances, extends tape lifespan |

Wear and Aging Resistance | Durable against wear and aging |

Flexibility | Good flexibility for easy wrapping |

Adhesive Performance | Strong adhesion, compatible with wire insulation |

Typical Use | Preferred for engine wiring harnesses where high temperature and oil resistance are critical |

Cost Consideration | More expensive than PVC tape, used selectively |

PE and PP

Polypropylene (PP) is often used as corrugated tubing in car wire harnesses. PP has a high melting point, excellent flame resistance, and low thermal conductivity. These properties make it ideal for protecting wires near engines, where heat and vibration are common. PP tubing shields wires from abrasion and helps prevent fire hazards. Polyethylene (PE) also appears in some coverings, but its specific properties are less documented. Both materials help meet safety standards and keep wires safe from damage.

PA6/66

Polyamide, known as PA6 or PA66, is another material used for protective sleeves. While specific temperature data is not always available, PA6/66 is valued for its mechanical strength and abrasion resistance. This material helps protect wires in demanding environments, especially where durability is important.

The table below summarizes the temperature ranges for these protective materials:

Material | Temperature Range (°C) | Notes |

|---|---|---|

Polyester (GREMFLEX® PET H&L) | -50 to 150 | Continuous working temperature |

Polypropylene (PPSS) | -15 to 60 (short term up to 80) | Corrugated conduit |

Polyethylene Terephthalate (PET, MCC series) | -70 to 125 | Braided sleeve |

Nylon (Polyamide PA6) | N/A | No explicit temperature range found |

Polyethylene (PE) | N/A | No explicit temperature range found |

PA6/66 (Polyamide 6/66) | N/A | No direct temperature data found |

Polyester and PET sleeves offer the widest temperature range, making them suitable for the most demanding areas in car wire harnesses.

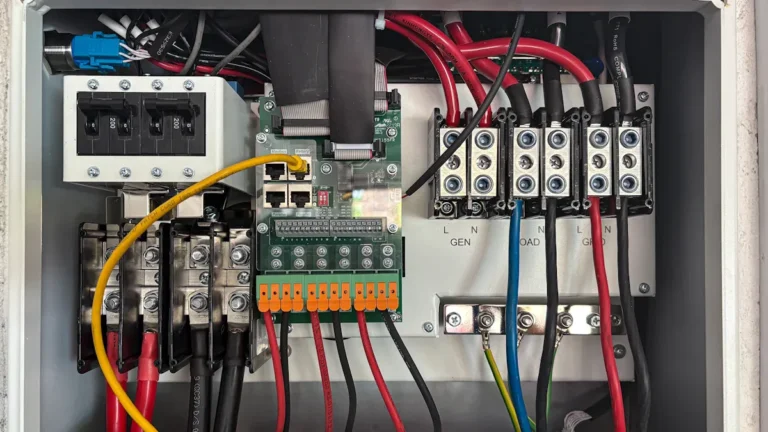

Terminals and Connectors

Brass

Brass is a popular choice for car wire harness terminals and connectors. This metal is a red alloy made from copper and zinc. Brass offers good electrical conductivity, which helps electricity flow easily through connections. Many car manufacturers use brass for battery terminals because it creates strong mechanical connections. These terminals come in many sizes and shapes, so they fit different battery types.

Brass resists corrosion, but not as well as bronze. In harsh environments, brass terminals need regular inspection and cleaning to prevent corrosion. Some manufacturers add a thin layer of tin to brass terminals. This coating improves corrosion resistance and helps the terminals last longer.

Brass also has good elasticity. This means it can bend slightly without breaking, which helps keep connections secure even when the car vibrates. Brass is less expensive than bronze, making it a cost-effective option for many vehicles.

Tip: Brass terminals work well for most cars, but they need extra care in places with high chlorine or salt.

Properties of Brass and Bronze in Terminals and Connectors:

Material | Electrical Conductivity | Corrosion Resistance | Additional Notes |

|---|---|---|---|

Brass (CuZn) | Good, better than bronze alloys | Moderate, less corrosion resistant than bronze | Good elasticity, often tin-plated to improve corrosion resistance |

Tin Phosphor Bronze (CuSn) | Lower than brass | High corrosion resistance | Good elasticity, fatigue strength, higher cost (~5x brass) |

Wrinkled Bronze (CuBe) | Close to brass | Good corrosion resistance | Strong voltage resistance |

Bronze

Bronze is another important material for car wire harness connectors. This alloy contains copper and tin. Bronze has lower electrical conductivity than brass, but it offers much better corrosion resistance. Bronze terminals can last 80 to 100 years or more with proper maintenance. This makes bronze a good choice for cars that operate in harsh environments.

Bronze also has high strength and durability. It handles stress and friction well, so it works best in places where connectors face a lot of movement or vibration. Bronze costs more than brass, but its long lifespan and resistance to wear make it worth the investment for demanding applications.

Lifespan and Performance Comparison:

Material | Typical Lifespan in Automotive/Harsh Environments | Maintenance Requirements | Corrosion Resistance | Strength and Durability |

|---|---|---|---|---|

Bronze | 80 to 100 years or more with proper maintenance | Needs proper maintenance | Superior, suitable for harsh environments | High, preferred for high stress and friction |

Brass | Shorter than bronze | Needs regular inspection and cleaning | Good, but less than bronze | Moderate, commonly used for battery terminals |

Bronze terminals provide excellent corrosion resistance.

They last longer than brass in harsh conditions.

Bronze is preferred for high-stress and high-friction areas.

Brass is more common for battery terminals due to its conductivity and lower cost.

Note: Both brass and bronze terminals often receive coatings of tin, gold, nickel, or silver. These coatings further improve their performance in automotive wire harnesses.

Binding and Organization in Car Wire Harnesses

Rubber

Rubber is a common material for binding and organizing wires in car wire harnesses. It offers flexibility and good resistance to abrasion. Silicone rubber, in particular, provides a tensile strength between 8 and 10 MPa. This strength helps keep wires secure during movement and vibration. Rubber also resists heat and chemicals, making it suitable for engine compartments. However, rubber can degrade over time when exposed to oil or extreme temperatures.

Vinyl

Vinyl, often in the form of PVC tape, is widely used for wrapping and bundling wires. It provides a cost-effective solution for organizing cables. Vinyl tape stretches easily and sticks well to insulation. It resists moisture and mild chemicals, which helps protect the harness from environmental damage. Vinyl does not perform as well as rubber in high-heat areas, but it works well for general wiring.

Electrical Tape

Electrical tape, made from materials like thermoplastic elastomer (TPE) or cross-linked polyolefin (XLPO), secures and insulates wire bundles. TPE and XLPO both offer a tensile strength of about 10.3 MPa, which means they hold wires tightly and resist breaking. XLPO stands out for its higher mechanical strength and durability. Electrical tape is easy to apply and remove, making it a practical choice for repairs and maintenance.

Material | Typical Tensile Strength (MPa) |

|---|---|

Silicone Rubber (SIR) | 8 to 10 |

Thermoplastic Elastomer | 10.3 |

Cross-linked Polyolefin | 10.3 |

Woven String

Woven string, sometimes called lacing cord, helps organize and bundle wires neatly. It is lightweight and flexible, allowing technicians to tie wires in tight spaces. Woven string resists abrasion and does not add much bulk to the harness. However, it may not provide as much protection against moisture or chemicals as rubber or vinyl.

Bio-sourced Materials

Some manufacturers use bio-sourced materials, such as soy-based plastics, for insulation and binding. These materials help reduce environmental impact. However, they can attract rodents like rats, mice, and squirrels. Rodents chew on these materials because of their texture and taste, which can lead to serious problems:

Rodents often enter engine compartments and chew on soy-based insulation.

Chewed wires can cause electrical failures and malfunctioning safety systems.

Rodent damage sometimes leads to costly repairs and even car fires.

Many vehicle owners report hidden damage that only appears after a malfunction.

Automakers have faced lawsuits over rodent-related wiring issues.

Regular inspections and preventive measures help reduce the risk of rodent damage in vehicles using bio-sourced materials.

Choosing Materials

Performance

Engineers select materials for car wire harnesses by looking at several performance factors. Each material must meet strict safety and durability standards. The most important criteria include weight, conductivity, durability, and safety. Lighter harnesses help vehicles move faster and use less fuel. Copper provides the highest conductivity, but aluminum is lighter and cheaper. Insulation materials like PVC and XLPE protect wires from heat, moisture, and vibration. Safety features, such as fire-resistant tapes and heat shrink tubing, prevent short circuits and fire hazards. The table below shows how different materials perform on key criteria:

Performance Criteria | Description | Material Performance |

|---|---|---|

Weight | Affects speed and fuel efficiency | Aluminum is lighter than copper |

Conductivity | Impacts current flow and efficiency | Copper is best; aluminum is less conductive |

Durability | Withstands heat, moisture, and vibration | PVC, XLPE, and copper offer strong protection |

Safety | Prevents failures and fire hazards | Fire-resistant tapes and proper insulation improve safety |

Design/Layout | Affects installation and repair | Compact design and routing help with safety and maintenance |

Proper wire gauge and routing also improve performance and safety.

Cost

Cost plays a big role in material selection for car wire harnesses. Copper remains the industry standard, but its price can change quickly. Aluminum is becoming more popular because it costs less and reduces vehicle weight. However, rising raw material prices can affect both copper and aluminum. Advanced composites are gaining interest, but their costs are not always clear. The table below compares the cost impact and market share of common materials:

Material Type | Market Share (2023) | Key Advantages | Cost Impact and Trends |

|---|---|---|---|

Copper | High durability and conductivity | Price changes add cost pressure | |

Aluminum | Growing | Lightweight, reduces vehicle weight | Raw material cost affects pricing |

Advanced Composites | Increasing | Lightweight | No clear cost data |

Manufacturers must balance performance with cost to keep vehicles affordable.

Application

The application environment shapes material choices for car wire harnesses. Engineers consider heat, moisture, chemicals, and vibration. For harsh conditions, they use sealed connectors and materials like nylon or PTFE. Mechanical strength and flexibility matter for areas with lots of movement. Electrical needs, such as current and voltage, guide wire gauge and connector type. Standards like AWG and ISO ensure safety and compatibility. The steps below show how application needs influence material selection:

Check environmental conditions, such as temperature and moisture.

Choose materials that resist abrasion and chemicals.

Select wire gauge and connectors based on electrical needs.

Make sure all parts meet industry standards.

Balance cost, performance, and availability.

Matching materials to the vehicle’s needs ensures reliable and safe operation.

Car Wire Harnesses use materials like copper, aluminum, PVC, and nylon for their unique strengths. Each material offers benefits such as flexibility, heat resistance, or cost savings. Choosing the right material ensures safety and long-lasting performance. When selecting materials, consider this checklist:

Check temperature and environment.

Match material to electrical needs.

Review cost and durability.

Confirm safety standards.

Careful selection helps every vehicle stay reliable on the road.

FAQ

What is the most common conductor in car wire harnesses?

Copper serves as the most common conductor. It provides excellent electrical conductivity and flexibility. Most car manufacturers choose copper for its reliability and long lifespan.

Why do some car wires use aluminum instead of copper?

Aluminum weighs less and costs less than copper. Engineers use aluminum to reduce vehicle weight and save money. Aluminum wires need to be thicker to carry the same current as copper.

How do insulation materials protect car wires?

Insulation materials like PVC, XLPE, and Teflon shield wires from heat, moisture, and chemicals. These materials prevent short circuits and keep the wires safe in harsh environments.

Can rodents damage car wire harnesses?

Rodents sometimes chew on bio-sourced insulation materials. This can cause electrical problems and expensive repairs. Regular inspections help prevent rodent damage.

Are all car wire harnesses made with the same materials?

No, car wire harnesses use different materials based on the vehicle’s needs. Engineers select materials for performance, cost, and the environment where the wires will operate.