Cómo Tesla establece el estándar para los requisitos del arnés de cableado en 2025

Tesla is ahead in making new Wiring Harness Requirements for 2025. In electric cars, a wiring harness links power, data, y sensores. It helps important systems work for safety and performance. Tesla uses new designs and trains workers carefully to make sure things work well.

Wiring harnesses must handle heat, shaking, and rust.

They help with new features like updates sent over the air and keep high-voltage parts safe.

More people want wiring harnesses for electric cars because of new tech and safety needs.

Control de llave

Tesla makes wiring harnesses shorter and lighter. This helps cars weigh less and use less energy. Only trained technicians can work on Tesla’s high-voltage wiring harnesses. This keeps everyone safe. Tesla uses strong materials that can handle heat. Their smart designs help wiring harnesses last longer and stay safe. Modular wiring and machines help Tesla build cars faster. This also makes cars cost less and have fewer mistakes. Tesla’s new wiring harness ideas set new rules for the industry. This makes electric cars safer and smarter.

Philosophy

Design Approach

Tesla has its own way of making wiring harnesses. The company wants electric cars to be safer and lighter. They also want cars to be easier to build. Tesla engineers follow some main ideas when they work:

They try to use less wiring in each car. Por ejemplo, Model Y has about 100 meters of wiring. Model 3 has 1,500 meters, even though both cars share many parts.

Power and data can move together in one cable. Smart chips and USB Type-C help control this at the cable ends.

Tesla is moving away from old 12V systems. New cars use higher voltage like 48V from the main battery.

Flex circuits sometimes take the place of normal wires. These circuits bend and fit into small spaces.

Tesla makes and patents “Structural Cables.” These cables are stiff enough for robots to put in during assembly.

Special connectors help machines attach wiring harnesses at the end of building.

Engineers plan wiring harnesses early in the design process. They work with other teams to make sure everything fits and works.

Tesla uses special software to help design wiring harnesses. This software makes 3D models and detailed plans for building.

Cooling systems for supercharging cables let wires be smaller and lighter. These wires can also carry more power.

Tesla tries to use the same connectors for charging in different places.

Technician Training

Tesla spends money on training so technicians can work safely. The Independent Repair Training Program has classes like “High Voltage and Electrical Systems” (HVE201). This class teaches how to fix and care for wiring harnesses. Students must know electrical basics and how to read wiring diagrams. The program also teaches how to find and fix problems in electrical systems.

Program Name | Área de enfoque | Requirements |

|---|---|---|

Harness repair, diagnostics, seguridad | Electrical knowledge, diagram skills | |

General Electrical Training | Broader electrical system diagnostics | Foundational electrical skills |

Tesla’s way makes sure only trained people work on wiring harnesses. This is extra important in high-voltage areas. Good training helps keep cars safe and working well.

Wiring Harness Requirements

Simplification and Weight Reduction

Tesla makes wiring harnesses simpler and lighter. The Tesla Model S used about 3 kilometers of wiring. The Model 3 used only 1.5 kilometers. For 2025, the Model Y will use just 100 meters. This is a big change from new designs and better layouts.

Tesla Model | Wiring Harness Length | Reduction Compared to Previous Model |

|---|---|---|

Tesla Model S | ~3 kilometers | N/A |

Model 3 | ~1.5 kilometers | 50% reduction from Tesla Model S |

Model Y (2025 projection) | ~100 meters | Approx. 93% reduction from Model 3 |

Tesla puts control units near sensors and motors. This means wires are shorter and there are fewer of them. Ethernet ring networks replace many old wires with fast, light cables. These changes make the wiring harness arriba a 73% lighter in some cars, like Cybertruck. Lighter cars use less energy and can drive farther.

Tesla switches from 12-volt to 48-volt systems. This lets engineers use thinner wires and less copper. Over 90% of the car uses the same connector. This makes building cars faster and cheaper. The charging port also uses fewer and lighter wires to connect to the main battery.

Making wiring harnesses simpler and lighter saves money. Tesla uses fewer materials and makes assembly easier. Local factories, like in Mexico, help lower costs by making harnesses close to where cars are built.

Nota: Shorter wiring harnesses mean fewer problems. This makes Tesla cars more reliable and easier to fix.

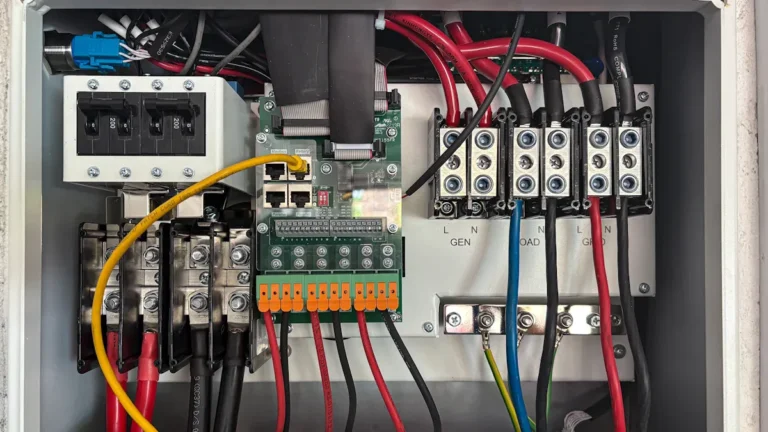

Safety Protocols

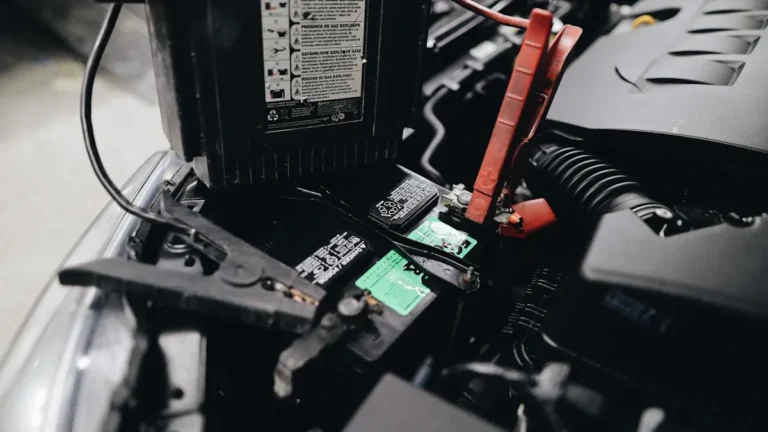

Tesla has strict safety rules for wiring harness work. Only trained and certified technicians can fix or change the wiring harness. This is very important for high-voltage or restraint systems. These rules keep people safe and protect the car.

Technicians must finish special training before working on high-voltage parts or the charging port.

Workers must wear personal protective equipment, like gloves rated for 1000 voltios, when handling high-voltage cables.

Before any repair, the high-voltage system and restraint system must be turned off.

Never cut or disconnect orange high-voltage cables unless the system is off.

Remove all jewelry and metal objects before touching high-voltage parts.

Use test tools rated for at least 500 volts when checking circuits.

Handle connectors with care. Do not pull on the wiring harness or force connectors apart.

Keep connectors clean and dry. Protect them from oil, coolant, or water.

After reconnecting, check that connectors are secure by gently pulling on them.

Follow special steps for airbag and seat belt systems. Only Tesla Service Centers or trained specialists can repair these parts.

Always keep an electrical safety hook nearby in case of emergency.

Aspecto | Industry Standards (Typical OEMs) | Tesla’s Approach |

|---|---|---|

Multiple levels defined by OEMs | Only trained technicians who complete all required certification courses | |

High-Voltage Work Authorization | Levels specify what procedures a technician can perform | Only technicians trained in High Voltage Awareness and certified can perform HV disablement and wiring harness repairs |

PPE Requirements | Mandatory use of appropriate PPE and insulating gloves rated for HV work | Requires PPE and insulating HV gloves with minimum class 0 (1000V) rating during HV cable handling |

Repair Restrictions | OEMs specify detailed repair protocols and technician levels for various components | Certain repairs (P.EJ., Supplemental Restraint System circuits) restricted to Tesla Service Centers or specialized technical specialists |

Tesla’s wiring harness rules are even stricter than most companies. Untrained people cannot work on the charging port or high-voltage systems. This helps stop accidents and keeps everyone safe.

Consejo: Always follow Tesla’s safety steps when working on the wiring harness or charging port. Safety comes first.

High-Voltage Wiring Harness System

Component Quality

Tesla uses special materials and smart designs for every high-voltage wiring harness. Each cable must carry strong electric currents and stay safe from heat, shaking, and water. Tesla picks winding tinned annealed copper for the conductor. This material is strong and bends easily. The insulation is made from heat-resistant, halogen-free compounds. These can work in very hot places, from 120°C to 200°C. A braided shield of tinned copper wraps around the conductor. This shield blocks outside signals and keeps the system safe from interference.

The outer sheath is made from plastics like PVC, HF-XLPO, TPE-E, PP-FR, or ETFE. These plastics can handle heat up to 180°C and do not catch fire easily. Tesla colors the outside orange to warn workers about high voltage. The company also uses self-coiling braided sleeves for most cables. For parts near the rear drive motor or heater, Tesla uses corrugated conduits. These choices help protect the wiring harness in tough places.

Tesla uses the 150 XLE High Voltage Shielded Battery Cable in many cars. This cable is soft and bends easily, which helps when building cars. Por ejemplo, the Model S charging port uses a 50 mm² cable. The Model 3 uses a 95 mm² cable. Tesla follows connector standards like SAE J1742 and makes sure there is at least IP65 protection. The company also uses color coding for polarity and phases. This makes repairs safer and easier.

Specification Category | Detalles |

|---|---|

Conductor | Winding tinned annealed copper |

Aislamiento | Heat resistant, halogen-free, rated 120°C-200°C |

Shielding Layer | Tinned annealed copper wound braid |

Outer Sheath | Heat resistant (105°C-180°C), CLORURO DE POLIVINILO, HF-XLPO, TPE-E, PP-FR, ETFE |

Voltage Ratings | DC 1000V, AC 660V; Harness rated AC 750V |

Color Coding | Orange sheath (GB30), extra colors for polarity/phases |

Connector Standards | SAE J1742, IP65 minimum |

Cable Structure | Single-core and multi-core round cables |

Nota: Tesla’s high-voltage wiring harness system uses top materials and follows strict design rules. This keeps the battery system safe and working well.

Safety and Durability

Tesla makes every high-voltage wiring harness to meet the highest safety rules. All technicians must finish special training before working on high-voltage systems. Each worker must wear gloves rated for 1000 voltios, safety glasses, and use test tools for 500V DC or more. Tesla’s service manual tells workers to check for high voltage before repairs. They must remove all metal objects and use only approved tools. These steps help stop electric shock and other dangers.

Inside the battery, Tesla uses two contactors that stay open unless the Battery Safety Monitor says it is safe. This system checks for problems all the time. If it finds a problem, it opens the contactors and stops high voltage. This watchdog feature keeps workers and the car safe during shipping, building, and use.

Tesla’s high-voltage wiring harnesses must pass many tests. The company checks for heat, frío, and rust resistance. Each harness uses insulation and connectors that resist chemicals and water. Tesla follows rules like ISO 26262 por seguridad, IEC 62196 for connectors, e iso 6722 for insulation. The company also meets US FMVSS and EU ECE rules for safety. Factories use quality control systems like ISO 9001 and UL approvals to make sure every harness is strong and safe.

Tesla tests harnesses for:

Heat and cold resistance

Rust protection

Chemical exposure

Vibration and shock

Flame retardancy (UL94 V-0 standard)

All materials must be recyclable and follow environmental rules in the US, UE, and China.

Tesla uses strict handling rules to keep harnesses clean and safe from damage.

Consejo: Tesla’s high-voltage wiring harness system keeps people and the car safe by using strong materials, smart design, y strict safety rules.

Innovations

Modular Design

Tesla is a leader in modular wiring harness design. The company has patents for making wiring harnesses simpler and easier to build. Tesla puts distributed controllers inside car parts like doors. These controllers handle many jobs right where they are. Only two wires connect each part to the main data bus. This makes the wiring harness shorter and less complicated.

Tesla’s modular wiring uses flat wires and connectors that snap together like Lego. Robots can put these harnesses in during assembly. This cuts down on manual work by more than 80%. The main wires for power and data have shields to block interference. Tesla also uses special paint and glue that conduct electricity in the car body. This helps robots build cars and saves money.

Innovation Aspect | Descripción | Impacto |

|---|---|---|

Distributed Controllers | Local control in components like doors | Shorter wiring, less complexity |

Flat Wiring & Conectores | Flat harnesses with snap-together connectors | Faster, automated assembly |

Modular Architecture | Backbone wiring with EMI shielding, integrated into car body | Supports robotic installation, cost savings |

Tesla’s modular design helps with the charging port too. The charging port wiring is part of the main harness. This makes repairs and upgrades easier.

Automatización

Tesla uses smart machines to make wiring harnesses better. The company uses software to plan and check wiring harness designs. This software makes digital twins. Engineers use these twins to test and improve the process before building real parts.

Automation makes sure every wiring harness is high quality. Sistemas de ejecución de fabricación (Mes) track each harness from start to finish. These systems give codes to every wire bundle and watch every step. They collect data to check quality. This helps Tesla find and fix problems fast.

Tesla is moving away from old CAN bus systems. The company uses automotive Ethernet and new protocols to connect control units. This change supports zonal architectures. It makes wiring harnesses smaller and easier for robots to install. The new system can handle lots of data, like video and diagnostics. It also keeps the charging port connected with fewer wires.

Nota: Tesla’s focus on modular design and automation sets a new standard for wiring harness innovation in electric vehicles.

Impacto

Actuación

Tesla’s new wiring harness ideas help make cars safer and more reliable. They also make building cars easier. Tesla used to have over 200 connector types. Now, there are only six. These six connectors work for almost all power and signal needs. Using fewer connectors means it is easier to build cars. It also means there are fewer mistakes.

Each connector has a seal for one wire and a lock. This keeps the connection tight and safe from dirt or water.

The connectors are spaced for 48V systems. This is under the 62V safety limit. It makes the system safer.

The 48V system uses less current and loses less power. Wires can be thinner and lighter. This lowers the chance of electrical trouble.

These changes help with self-driving and better power use. The car’s systems work better and break less often.

Tesla sometimes uses aluminum wires between the charger and plug. Aluminum is lighter and costs less than copper. This helps make the car lighter and cheaper. Tesla’s new ways of building fix the usual problems with aluminum. Most other car makers still use copper. Tesla’s way is different.

Tesla Low-Voltage Connector Standard makes wiring simple. It is also easy to build. Tesla shares these connector designs with others. This helps other companies make better systems.

Tesla’s wiring harness changes make cars safer, more reliable, and easier to build.

Industry Trends

Many car companies now copy Tesla’s wiring harness ideas. The industry wants harnesses that are small, light, and strong. More cars use fiber optics for fast data and less noise. Modular wiring makes it easy to fix or upgrade cars.

People want more safety and comfort features, like ADAS and infotainment.

Fiber optics give fast data for self-driving and car-to-car talk.

Modular harnesses make repairs and upgrades simple.

Harnesses must work with high-voltage electric systems.

Companies care about strong, reliable harnesses and new ways to build them.

The world market for car wiring harnesses is growing quickly. By 2025, it will be worth $67.4 mil millones. It may almost double by 2035. Electric cars need more complex harnesses for things like climate control and battery care. Asia Pacific, América del norte, and Europe lead this growth. Governments and new money help this happen.

The future of wiring harnesses will focus on lightweight, modular, and smart designs, with Tesla setting the pace for the industry.

Tesla’s new wiring harness ideas are changing the rules for 2025.

Domain-based electrical systems split the car into zones. This makes harnesses lighter. It also makes them easier to fix.

Modular designs and strong connectors help keep cars safe. They also make cars work better, even in tough places.

Smart connectors and machines help lower costs. They also make repairs faster.

Tesla Low Voltage Connector Standard helps other companies use the same parts.

As Tesla stays ahead, cars will get safer, smarter, and more efficient in the future.

Preguntas frecuentes

What makes Tesla’s wiring harness different from other car brands?

Tesla’s harnesses are shorter and lighter than most. They use fewer connectors than other brands. Engineers make them easy to put together. The harnesses are also very safe. Tesla uses special materials and modular layouts. This helps Tesla set new standards for electric cars.

Who can repair or modify a Tesla wiring harness?

Only trained and certified technicians can work on them. Tesla asks for special training for high-voltage and restraint systems. This rule keeps workers and cars safe.

Why does Tesla use orange cables in high-voltage systems?

Orange cables show that there is high voltage. The color helps workers see dangerous wires fast. Tesla uses orange to follow global safety rules for high-voltage parts.

How does Tesla’s wiring harness design help the environment?

Tesla uses less material and lighter wires. Factories build harnesses close to where cars are made. This cuts down on waste and lowers shipping pollution. Tesla also picks recyclable materials for many harness parts.