가전제품용 와이어링 하네스 솔루션이란 무엇이며 왜 중요한가요?

Wiring harness solutions for home appliances organize and connect wires, 터미널, and connectors inside devices like refrigerators and washing machines. These systems play a vital role in keeping appliances safe and reliable. When wiring fails in a washing machine, the appliance may stop working, or worse, cause electrical hazards.

Home appliances make up about 20% of the global wire harness assemblies market, with Asia-Pacific leading in production and demand. This highlights how essential proper wiring harness solutions for home appliances are to everyday life.

주요 시사점

Wiring harnesses organize and protect electrical wires inside home appliances, ensuring safe and reliable power and signal flow.

These harnesses improve appliance safety by preventing short circuits, overheating, and electrical hazards through strong insulation and secure connections.

Custom wiring harnesses fit specific appliance designs, saving space and enhancing performance with materials chosen for durability and safety.

Wiring harnesses simplify installation and maintenance by bundling wires neatly and using labels and modular designs for easy repairs.

Smart wiring harnesses support modern features like IoT connectivity and real-time monitoring, helping appliances work smarter and last longer.

Wiring Harness Solutions for Home Appliances

What They Are

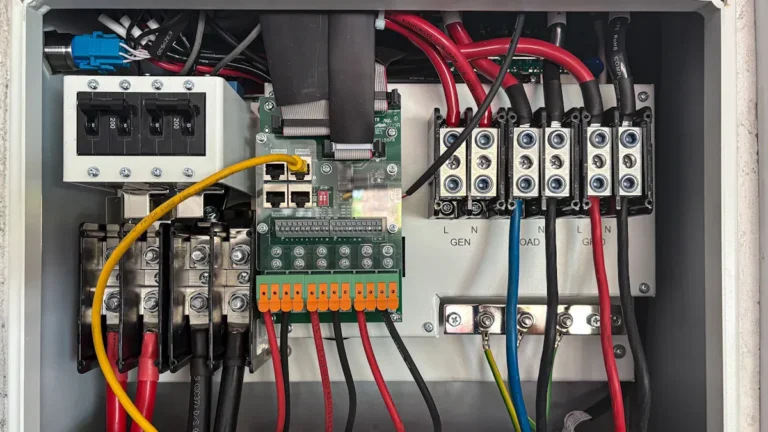

Wiring harness solutions for home appliances are structured groupings of wires, 커넥터, and terminals that transmit power and data inside devices. These harnesses organize electrical pathways, making sure each part of an appliance receives the right signals and energy. Unlike traditional loose wiring, harnesses bundle cables together, which helps keep the inside of appliances neat and safe.

A typical wiring harness includes several important components:

커넥터: Securely join wires to different parts, such as plugs, sockets, and terminal blocks.

터미널: Endpoints of wires that ensure reliable connections, often crimped or soldered.

Tapes and Sleeves: Protect and insulate wires, preventing short circuits.

Switches and Relays: Control the flow of electricity and activate circuits.

Holders and Breakers: Hold wires in place and protect against too much current.

Diodes and Resistors: Manage the direction and resistance of electrical signals.

Sensors and Actuators: Detect changes and convert signals into actions.

Circuit Breakers: Stop the flow of electricity during faults to protect the system.

세부 / 예 | |

|---|---|

Core Components | 와이어, 커넥터, winding tapes |

Electrical Parts | Switches, holders, breakers, diodes, resistors, 센서, 액추에이터 |

Cable Materials | UL/CSA, CE, vde, 날씨, CB certified wires |

커넥터 유형 | Deutch, JST, Tyco, JAE, Hirose, Molex, AMP (customer-specific) |

Cable Preparation Methods | Trimming, 스트리핑, tin coating, 뒤틀림 |

Protective Elements | Tapes, sleeves, heat shrinking, binding, bolting, strain relief molding, inner and outer molding |

Assembly Types | Power transmission cable assembly, signal transmission wire harness assembly, audio/video cables |

Functional Assemblies | Wiring harnesses for feedback protection, interconnection between modules, communication components |

Wiring harness solutions for home appliances differ from traditional wiring methods. Harnesses are pre-assembled bundles designed for easy installation and fewer mistakes. Manufacturers select materials and connectors based on the appliance’s needs, such as heat-resistant insulation for ovens or UL-rated wires for refrigerators. Quality control steps, like labeling and color-coding, help prevent errors and ensure safety.

메모: Wiring harnesses bundle cables for easier installation and better protection against heat, 수분, 그리고 진동. This approach improves reliability and safety compared to loose wiring.

How They Work

Wiring harness solutions for home appliances transmit power and data by connecting all the electrical parts inside a device. The harness acts like a central nervous system, sending energy to motors, lights, and control panels, while also carrying signals from sensors and switches.

측면 | 설명 |

|---|---|

Power Transmission | Distributes main power to high-power components like motors, compressors, and heating elements. |

Signal Control | Connects control panels, 센서, and main boards for smart operation and fault detection. |

Internal Connections | Links different units, such as indoor and outdoor parts of air conditioners. |

Safety Features | Includes insulation, fireproofing, leak prevention, and temperature resistance. |

Reliability & 내구성 | Protects against vibration, 부식, and moisture, especially in harsh environments. |

Electromagnetic Compatibility | Uses shielding to prevent interference in high-frequency circuits. |

Intelligent Integration | Supports IoT connectivity, modular designs, and environmental compliance. |

Wiring harness solutions for home appliances use several features to ensure smooth operation:

High-speed data transfer: Supports fast communication for smart appliances.

Robust power management: Delivers stable power, reducing surges and outages.

Modular design: Allows easy upgrades and repairs.

EMI/RFI 차폐: Protects signals from interference.

Durability and safety: Uses heat-resistant and waterproof materials.

특징 | 설명 |

|---|---|

High-Speed Data Transfer | Supports fast data communication for smart devices, ensuring minimal latency. |

Robust Power Management | Ensures stable, regulated power supply to connected devices, reducing surges and outages. |

모듈형 디자인 | Allows easy expansion and integration of new smart devices and systems. |

EMI/RFI Shielding | Protects data transmission from electromagnetic and radio-frequency interference. |

Future Compatibility | Designed to support emerging smart home technologies and devices. |

내구성 & 안전 | Made with heat-resistant, waterproof materials meeting safety standards for long-lasting use. |

Wiring harness solutions for home appliances also improve organization and safety. They bundle wires into a single unit, which reduces clutter and makes installation easier. This design protects wires from damage, prevents short circuits, and helps appliances last longer.

Benefit Category | Explanation |

|---|---|

Bundles multiple wires into a single unit, reducing clutter and simplifying installation. | |

Enhanced Safety and Durability | Protects wires from damage, prevents short circuits, and resists wear from vibration and temperature. |

Energy Efficiency and Power Management | Ensures efficient power distribution, improving performance and reducing energy use. |

Reduced Maintenance Costs and Downtime | Organized wiring makes troubleshooting easier and extends appliance lifespan. |

Reduced Risk of Electrical Fires | Uses high-quality insulation and heat-resistant materials to lower fire risk. |

The market for wiring harness solutions for home appliances continues to grow. Home appliances hold a 20% share of the global wiring harness market, driven by the rise of smart technology and IoT integration.

Key Benefits

Organization and Space-Saving

Wiring harness solutions for home appliances help manufacturers solve many organizational challenges, especially in compact devices. These harnesses keep wires neat and bundled, which makes the inside of appliances look clean and organized. By grouping power, signal, and control lines together, they simplify complex wiring systems. This approach saves space and allows for more compact appliance designs.

Manage limited internal space with flexible layouts that fit tight enclosures.

Protect wiring from heat and moisture using insulated and sealed harnesses.

Reduce assembly line errors by providing labeled, pre-configured harnesses.

Simplify multi-circuit complexity by integrating different lines into a single system.

Ensure certification and compliance with documented, test-verified harnesses.

Organized wiring not only saves space but also makes installation and maintenance easier for technicians.

Protection and Durability

Wiring harness solutions for home appliances use strong materials and smart designs to protect wires from damage. Manufacturers choose insulation materials like PTFE, ETFE, and FEP for chemical resistance. They use abrasion-resistant jackets made from cross-linked polyethylene or thermoplastic elastomers to guard against wear. Protective sleeves, 열 수축 튜브, and flexible conduits shield wires from heat, 수분, 그리고 진동. Sealed connectors with high IP ratings keep out water and dust.

Grommets, clamps, and cable ties provide strain relief and reduce stress on wires.

Regular inspections and quality standards ensure long-term safety.

Protective components such as tubes, foam, and tape shield wiring from humidity, 열, 먼지, and shocks.

Strict quality controls during manufacturing prevent defects and ensure that each harness meets industry standards. These steps help appliances last longer and work safely.

Efficiency and Performance

Wiring harness solutions for home appliances improve efficiency and performance in several ways. Lean manufacturing techniques, such as 5S visual management and just-in-time inventory, speed up assembly and reduce waste. Automated cut-strip-crimp lines and in-house testing labs catch defects early, which increases reliability.

Technique | Benefit for Appliance Efficiency |

|---|---|

5S Visual Management | Faster assembly, less unnecessary motion |

Single-Piece Flow | Shorter lead times, more flexibility |

Automated CSC Lines | Fewer defects, higher consistency |

In-House Testing | Early defect detection, better durability |

Wire harnesses also reduce the risk of short circuits and improve signal quality. They protect against environmental factors, which boosts reliability and lowers maintenance needs. By ensuring organized and durable electrical connections, these harnesses help appliances run smoothly and efficiently.

Safety and Reliability

Preventing Hazards

Wiring harness solutions for home appliances play a crucial role in preventing electrical hazards. Manufacturers use proper crimping and soldering techniques during assembly. These methods create strong, reliable connections that resist vibration and movement. When connections remain secure, the risk of short circuits, open circuits, and overheating drops significantly. Loose or poorly connected wires can cause electrical faults, but a well-designed harness keeps everything in place.

The following table highlights common electrical hazards and how wiring harnesses address them:

Electrical Hazard | Cause/Description | Risk Prevented by Wiring Harness Solutions |

|---|---|---|

Overloaded Circuits | Excess devices on one circuit causing overheating | Prevents overheating and electrical fires by proper wiring design |

Exposed Wiring | Wear, damage, or poor installation exposing live wires | Ensures insulation and protection to avoid shocks and shorts |

Improper Grounding | Lack of correct grounding path | Prevents electric shock and equipment damage |

Damaged Insulation | Aging or physical damage exposing wires | Maintains insulation integrity to prevent shocks and fires |

Loose Connections | Vibrations or poor installation causing intermittent or faulty connections | Secures connections to avoid arcing, overheating, and failures |

Inadequate Wiring | Undersized or improper wiring unable to handle load | Ensures correct wire sizing to prevent overheating and faults |

Properly assembled wiring harnesses help prevent fires, electric shocks, and equipment failures. This protection keeps homes and families safe.

Supporting Maintenance

Wiring harness solutions for home appliances also make maintenance easier and more efficient. Each wire in the harness often carries a label. These labels help technicians quickly identify the function of each wire. When a problem occurs, technicians can find and replace faulty parts without confusion. The modular design of many harnesses allows for quick removal and replacement of sections. This approach reduces repair time and lowers costs.

Labeled wires speed up troubleshooting.

Modular harnesses allow for easy upgrades and repairs.

Organized wiring reduces the chance of mistakes during maintenance.

Technicians benefit from clear layouts and accessible components. Homeowners experience less downtime and fewer unexpected failures. Reliable wiring harnesses support both safety and long-term appliance performance.

Design and Customization

Material Choices

Material selection shapes the safety, 내구성, and performance of wiring harnesses in home appliances. Engineers choose conductors, 격리, 커넥터, and protective components based on the appliance’s needs. 아래 표는 하이라이트 common materials and their key characteristics:

소재 카테고리 | Common Materials Used | Key Characteristics / Usage Context |

|---|---|---|

도체 재료 | 구리 (tinned/bare), 알류미늄, Stranded/Solid wire | High conductivity, corrosion resistance, 유연성, rigidity |

격리 & 외장 | PVC, 실리콘, TPE, LSZH, Heat-resistant fabrics | Flame retardant, temperature resistance, 유연성, 내마모성, low smoke/halogen-free |

커넥터 & 터미널 | Plastic connectors, Metal terminals, Sealed connectors | 경량, corrosion-resistant, waterproof/dustproof, precise fit |

Protective Components | Grommets, seals, mounting clips, Over-molding, 차폐, Heat-shrink tubing | Structural support, protection from environmental and electromagnetic interference |

Material choices affect how well a harness resists heat, 추운, and moisture. High-temperature materials like polyimide and fluoride polymers work well in ovens and dryers. Flexible insulation prevents wires from cracking in cold climates. Cross-linked polyethylene and PVDF insulation block moisture and corrosion. Protective sleeves and waterproof connectors keep wires safe from water and dust. Gold-plated connectors resist corrosion and improve reliability.

팁: Using the right materials helps appliances last longer and keeps users safe.

Custom Solutions

Modern appliances often need custom wiring harnesses to meet unique design challenges. Manufacturers tailor wire types, lengths, and connectors for each product. They select premium materials, such as copper wires and Teflon insulation, for better performance. Custom harnesses can include features like flame retardancy, 내열성, and moisture protection.

Special harnesses serve washing machines, coffee makers, air conditioners, and more.

Smart system integration supports real-time monitoring and diagnostics.

경량, high-strength materials reduce bulk and improve efficiency.

특징 | How It Addresses Unique Design Challenges in Modern Home Appliances |

|---|---|

Enables future upgrades and expansions without complete redesign. | |

Space Optimization | Bundles wires efficiently to maximize limited space in compact appliance designs. |

Precision Engineering | Tailors harnesses to exact specifications, 안정적인 성능 보장. |

Enhanced Safety | Designs harnesses to comply with strict safety standards and withstand environmental stresses. |

Faster Installation | Simplifies assembly, reducing installation time and errors. |

규정 준수 | Ensures adherence to industry-specific standards and certifications. |

혁신 | Incorporates modular designs and smart integration for advanced functionality. |

Custom wiring harnesses help appliances work better, last longer, and stay safe in any environment.

Compliance and Trends

Safety Standards

Manufacturers must follow strict safety and environmental standards when designing wiring harnesses for home appliances. 그만큼 IPC/WHMA-A-620 standard sets the global benchmark for quality and safety in wire harness assemblies. This standard defines requirements for materials, assembly methods, and testing procedures. It ensures that harnesses meet safety, workmanship, and performance criteria for consumer appliances.

Many organizations require additional certifications. UL approval confirms electrical safety. BIS compliance addresses Indian appliance standards. RoHS certification guarantees that harnesses are free from hazardous substances such as lead and mercury. CE marking signals readiness for global OEM production. Glow Wire testing checks fire resistance in high-heat environments.

Manufacturers also use traceability programs to track harnesses from production to final assembly. 그만큼 UL Wiring Harness Traceability program uses holographic labels and surveillance to prevent counterfeit products. These measures protect consumers and help companies maintain compliance across supply chains.

팁: Certified wiring harnesses reduce liability and protect brand reputation.

Certification/Standard | 목적 | Region/Scope |

|---|---|---|

IPC/WHMA-A-620 | Quality and safety for wire harnesses | Global |

UL/CSA/VDE | Electrical safety and flame resistance | US/Canada/Germany |

RoHS 규제 | Hazardous substance restriction | EU/Global |

CE | OEM production readiness | Europe/Global |

Glow Wire Test | Fire resistance in high-heat environments | Global |

Smart Integration

Recent trends show rapid growth in smart integration for wiring harnesses. Manufacturers embed IoT-enabled features such as micro-sensors for real-time diagnostics. These sensors track current, 전압, and strain, helping appliances predict failures before they happen. Enhanced machine-to-machine communication improves connectivity between devices.

Modular designs allow easy upgrades and repairs. Pre-assembled plug-and-play modules make installation faster and maintenance simpler. Interchangeable connectors and sub-harnesses support scalability. Smart connectors with embedded sensors and 3D-printed junctions enable advanced functionality.

Automation and AI-powered quality assurance improve manufacturing precision. Lightweight and flexible harnesses fit compact appliances. Manufacturers use eco-friendly, recyclable materials to support sustainability. Digital twins and simulation-based testing help engineers prototype and validate new designs quickly.

IoT sensors enable predictive maintenance and real-time monitoring.

Modular harnesses simplify upgrades and reduce labor costs.

EMI shielding protects data integrity in smart appliances.

Sustainability practices influence material choices and production methods.

Smart integration and modularity drive innovation in next-generation home appliances.

Wiring harness solutions for home appliances play a vital role in safety, 신뢰할 수 있음, 그리고 성능. High-quality materials, strict testing, and compliance with standards like ISO 9001 and IPC/WHMA-A-620 ensure dependable operation. Manufacturers now use advanced designs, eco-friendly materials, and smart features to meet modern needs. Consumers should check for 인증, 신뢰할 수 있는 공급업체, and positive reviews before purchasing. Choosing appliances with reliable wiring harnesses helps extend lifespan and improve satisfaction.

FAQ

What is the main purpose of a wiring harness in home appliances?

A wiring harness organizes and protects electrical wires inside appliances. It ensures safe power and signal transmission. This system helps appliances work reliably and reduces the risk of electrical hazards.

How do wiring harnesses improve appliance safety?

Wiring harnesses use strong insulation and secure connectors. These features prevent short circuits, overheating, and electrical fires. Manufacturers test each harness to meet strict safety standards.

Can a wiring harness be replaced or repaired?

Technicians can replace or repair wiring harnesses in most appliances. Modular designs and labeled wires make the process faster and easier. Always use certified parts for repairs.

Why do manufacturers choose custom wiring harnesses?

Custom harnesses fit specific appliance designs. They use materials and connectors that match the appliance’s needs. This approach improves performance, 안전, and space efficiency.

Are wiring harnesses important for smart home appliances?

예. Wiring harnesses support data transfer and power management in smart appliances. They enable features like remote monitoring, 진단, IoT 연결성.