Sutrumpinamas surinkimo laikas naudojant iš anksto sumontuotas ir modulines diržų sistemas, skirtas buitinių prekių gamybai

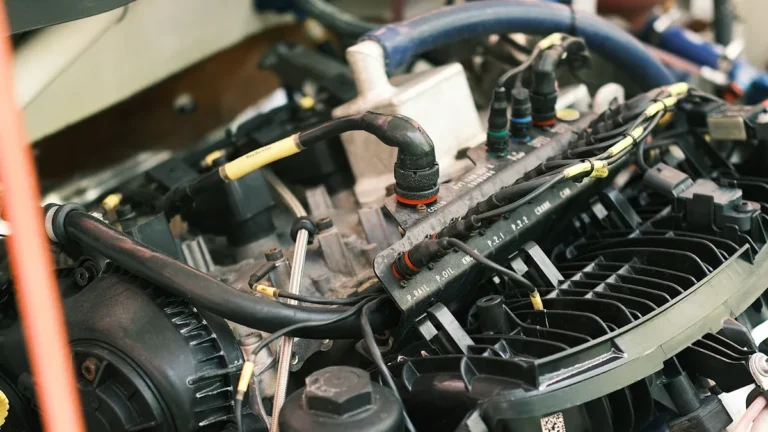

You often face delays when assembling white goods because workers search for the right wires and connectors. This slows down your production line and increases mistakes. Pre-kitted and modular harness systems solve this problem by reducing assembly time. In a busy factory, you need fast and accurate work to stay ahead of your competitors. „Yueqing Chengli Electronic Technology Co.“, Ltd. gives you expert wiring harness and kitting solutions that help you build appliances with fewer errors and greater speed.

Pagrindiniai takeliai

Pre-kitted harnesses save time by providing all necessary components in one package, allowing workers to focus on assembly instead of searching for parts.

Modular harness systems enhance efficiency by using standard modules that fit together easily, reducing assembly time and minimizing defects.

Implementing a kitting process streamlines production, sumažina klaidų skaičių, and improves inventory management, leading to higher quality products.

Custom kitting solutions allow manufacturers to tailor harnesses to their specific needs, enhancing brand identity and meeting customer expectations.

Integrating kitting into existing processes requires careful planning, training, and quality checks to ensure a smooth transition and sustained efficiency.

Reducing Assembly Time in White Goods Manufacturing

Impact of Pre-Kitted Harnesses

You want to speed up your assembly and kitting process. Pre-kitted harnesses help you do this by giving your workers everything they need in one package. When you use pre-assembled kits, you remove the need to search for wires or connectors. This step alone can save you a lot of assembly time. Your team can focus on putting together the appliance instead of sorting through parts.

Pre-kitted harnesses also help you avoid mistakes. When you have all the right parts in one kit, you lower the chance of missing or using the wrong component. This leads to fewer errors and less rework. You see a smoother assembly line and a faster production process.

Patarimas: Pre-kitted harnesses support production optimization by making sure every kit matches your appliance’s needs. This means you can keep your assembly line moving without delays.

You also improve manufacturing efficiency. Your workers do not waste time looking for parts. They follow a clear process, which helps you reach your production goals. Kitting helps you keep track of inventory and makes it easier to plan for future orders. You can see how kitting leads to better optimization and faster assembly.

Role of Modular Harness Systems

Modular harness systems take your assembly and kitting process to the next level. These systems use standard modules that fit together easily. You can use the same modules for different appliances, which helps you with production optimization. When you use modular harnesses, you cut down on assembly time because each module snaps into place quickly.

You also see fewer defects and less rework. The table below shows how modular harness systems improve your results on the assembly line:

Metrika | Poveikis |

|---|---|

Prevents defects during assembly | |

60% Fewer Recurring Defects | Identifies and eliminates root causes |

80-90% Lower Warranty Claims | Resolves claims faster and reduces costs |

You can see that modular harnesses help you reach a higher first pass yield. This means most products pass inspection the first time. You also see fewer recurring defects, which means you spend less time fixing the same problems. Lower warranty claims save you money and keep your customers happy.

Modular harness systems also support automation. You can use machines to put together modules, which makes your assembly line even faster. Automation and kitting work together to boost your manufacturing efficiency. You get a smoother process, less waste, and better use of your resources.

When you use modular harnesses, you make your assembly and kitting process more flexible. You can change modules to fit new appliance designs. This helps you keep up with changes in the market. Your production line stays efficient, and you keep reducing assembly time with every new project.

Kitting Process Explained

What Is Kitting in Manufacturing?

You see the kitting process every day in white goods factories. The kitting process means you gather all the parts needed for a specific job and put them together in one kit. When you use kitting manufacturing, you make sure each kit has the right wires, jungtys, and other components for the appliance you build. This method helps you work faster and with fewer mistakes.

Kitting manufacturing involves assembling individual components or raw materials into kits that are ready for use on the production line.

These kits include all necessary components for a specific task or assembly process.

The kitting process helps reduce errors, speed up production, and improve overall efficiency.

You do not need to search for parts during assembly. The kitting process gives you everything you need in one place. You save time and avoid confusion. You also keep your workspace organized. When you use kitting manufacturing, you help your team focus on building appliances instead of sorting through bins.

How Kitting Streamlines Assembly

The kitting process makes your assembly line run smoothly. You follow clear steps to prepare each wiring harness kit. Here is how the kitting process works for wiring harnesses in appliance manufacturing:

Cutting and Stripping Wires: You cut wires to the right length and strip the insulation.

Crimping or Soldering: You attach terminals to the wire ends for strong connections.

Terminal Assembly: You insert crimped terminals into housings or connectors.

Route and Bundle the Harness: You route and tie wires together based on the design.

Testing and Inspection: You test wires for continuity and check for damage.

Applying Protective Covering: You secure wires with protective materials for durability.

Ženklinimas ir ženklinimas: You label wires and connectors for easy maintenance.

Quality Approval and Packing Of Product: You inspect the final kit and pack it for delivery.

The kitting process in manufacturing gives you all the parts you need before you start assembly. You do not waste time looking for missing pieces. The kitting process helps you avoid delays and keeps your production line moving. You see fewer errors because each kit matches the appliance design. The kitting process also helps you manage inventory and plan for future orders.

When you use the kitting process, you boost productivity. Workers have everything they need at hand. The kitting process minimizes downtime and makes your job easier. You get more appliances built in less time. The kitting process supports your goal of efficient and accurate assembly. You see better results and higher quality products.

PASTABA: The kitting process is a key part of kitting manufacturing. You use it to organize your workflow and improve your factory’s output.

Benefits for Manufacturers

Faster Assembly and Fewer Errors

You want your manufacturing process to run smoothly. Pre-kitted and modular harness systems help you achieve faster assembly. Workers receive all the needed parts in one kit. This method supports material kitting and lean manufacturing. You see fewer mistakes because each kit matches the appliance design. Quality improves when you reduce errors. You spend less time fixing problems and more time building products. Material kitting also helps you keep track of parts, which boosts quality control.

When you use material kitting, you make your assembly line more efficient. You lower the risk of missing components. You also support waste reduction by using only what you need.

Cost and Labor Savings

You save money when you use material kitting in manufacturing. Workers spend less time searching for parts. This leads to labor savings. You also cut costs by reducing rework and scrap. Lean manufacturing practices help you use resources wisely. You see savings in both time and materials. Material kitting supports improved efficiency because you organize parts before assembly. You can train new workers faster since the process is simple and clear.

Here is a table showing how material kitting and modular harness systems help you save:

Nauda | Impact on Manufacturing |

|---|---|

Labor savings | Less time spent on sorting |

Cost savings | Fewer errors and less waste |

Kokybės kontrolė | Consistent product output |

Improved Quality and Inventory Control

You want high quality in every product. Material kitting helps you reach this goal. You control the parts that go into each kit. This supports quality control and lean manufacturing. You track inventory more easily because you know what goes into each kit. Waste reduction becomes possible when you use only the needed parts. You see better results in manufacturing because you focus on quality at every step.

Material kitting improves quality by reducing mix-ups.

You support quality control with clear labeling and organized kits.

Lean manufacturing and material kitting work together to boost efficiency and quality.

Patarimas: Use material kitting to improve quality control and keep your inventory organized. This helps you deliver better products and meet customer expectations.

Custom Kitting Solutions from Yueqing Chengli

Tailored Appliance Harnesses

You want wiring harnesses that fit your appliances perfectly. Yueqing Chengli gives you the power to choose exactly what you need. You can select custom logos, packaging, and even graphics for your harness kits. This flexibility helps you match your brand and meet your customers’ expectations. You do not have to order large quantities to get started. You can request as few as 10 pieces for each customization type. This makes it easy to test new ideas or launch special product lines.

Here is a quick look at your customization options:

Customization Type | Minimum Order Requirement |

|---|---|

Customized logo | 10 pieces |

Customized packaging | 10 pieces |

Graphic customization | 10 pieces |

You can see how these options help you stand out in the competitive world of appliance manufacturing. When you use tailored harness kits, you make your assembly process smoother and your products more unique.

Certifications and Quality Standards

You need wiring harnesses that meet strict safety and quality rules. Yueqing Chengli holds important certifications that show a strong commitment to quality. These certifications include:

IATF 16949 sertifikavimas for automotive cable assemblies and wire harnesses.

These certifications set high standards for safety, patvarumas, and environmental care. They give you confidence that your harnesses will work well and last long. You avoid costly recalls or fines because your products follow legal rules. The IPC/WHMA-A-620 standard guides the way wires get stripped, crimped, and soldered. ISO 9001 certification means that every step in the process is clear and repeatable. You get consistent results every time.

When you choose certified harnesses, you protect your reputation and your customers. You know that each harness meets the needs of modern manufacturing. You can trust that your appliances will pass inspections and perform safely in homes around the world.

Supporting Leading Brands

You want to work with a partner who understands the demands of top brands. Yueqing Chengli supports major names in the appliance industry, including Haier, Hisense, Panasonic, and Xiaomi. These companies trust Yueqing Chengli to deliver reliable harnesses for their products. You benefit from this experience because you get solutions that solve real assembly challenges.

Pavyzdžiui, you might need a harness kit that fits a new washing machine design. Yueqing Chengli can create a kit that matches your exact needs. If you face a problem with assembly speed, you can ask for a modular harness system that snaps together quickly. You get advice and support from a team that knows manufacturing inside and out.

You can see how custom kitting solutions from Yueqing Chengli help you stay ahead in the fast-moving world of appliance manufacturing. You get products that meet your needs, follow strict standards, and support your brand’s growth.

Implementation Strategies

Integrating Kitting into Existing Processes

You can improve your manufacturing process by adding kitting and modular harness systems. Start by looking at your inventory data. Find out which parts you use most often. Listen to your customers and learn what they want. Choose the right components for each kit. Standardize your kits so workers know what to expect. Write a bill of materials for every kit. Work with your suppliers to make sure you get parts on time. Pick packaging that keeps everything safe and organized. Label each kit with clear instructions. Set up a space in your warehouse for kitting operations. Check the quality of each kit before it goes to the assembly line.

Here are the steps you can follow for process optimization and better efficiency:

Analyze inventory data.

Assess customer demand and opinions.

Select components for each kit.

Standardize kits for common tasks.

Create a bill of materials.

Engage suppliers for timely delivery.

Choose packaging for each kit.

Label kits with identifiers and instructions.

Allocate warehouse space for kitting.

Implement quality assurance checks.

Training and Change Management

You need to help your team adjust to new systems. Treat changes as projects with clear goals and timelines. Build strong partnerships with everyone involved. Talk openly about risks and plans. Keep communication clear so everyone feels confident. When you train your workers, show them how kitting supports just-in-time manufacturing and boosts operational efficiency. Use hands-on training and simple guides. Encourage questions and feedback. This approach helps your team feel ready for new tasks.

Set clear objectives for the change.

Involve stakeholders early.

Plan for risks and keep everyone informed.

Use hands-on training and easy-to-follow guides.

Overcoming Common Challenges

You may face problems when you switch to kitting and modular harness systems. Sometimes, workers resist new methods. You can solve this by showing how kitting makes their jobs easier. If you run into supply delays, work closely with your suppliers. Use flexible systems that let you adapt to changes in demand. Focus on flexibility and adaptability to keep your manufacturing process strong. Track results and adjust your process as needed. This helps you keep efficiency high and meet your production goals.

Patarimas: Review your process often to find new ways to improve efficiency and support your team.

You can see how pre-kitted and modular harness systems make your assembly faster and more organized. The table below highlights the main benefits:

Benefit Description | Impact on Assembly Time and Efficiency |

|---|---|

Reduced final assembly labor | Increases efficiency and shortens project timelines |

Streamlined assembly process | Saves time and minimizes errors |

Cost savings through bulk orders | Lowers unit costs and reduces procurement steps |

Improved organization and labeling | Simplifies installation and maintenance |

Simplified ordering process | Speeds up project management |

To improve your process, you should:

Integrate automation to reduce errors.

Use advanced inventory management systems.

Invest in scalable solutions.

Plan workspaces for efficiency.

Add quality control checks.

Custom kitting from Yueqing Chengli helps you boost efficiency, improve quality, and stay competitive.

DUK

What is a pre-kitted harness system?

A pre-kitted harness system gives you all the wires and connectors you need for one appliance in a single package. You save time because you do not search for parts.

How do modular harness systems help you?

Modular harness systems use standard parts that snap together. You build appliances faster and change designs easily.

Patarimas: Modular systems help you keep your assembly line flexible.

Can you customize harness kits for your brand?

Taip, you can choose custom logos, packaging, and graphics for your harness kits.

Custom Option | Minimum Order |

|---|---|

Logo | 10 pieces |

Pakuotė | 10 pieces |

Graphics | 10 pieces |

What certifications do Yueqing Chengli harnesses have?

You get harnesses certified with CE, Ul, IATF 16949, ir ISO 9001. These certifications show high safety and quality standards.

How do you start using kitting in your factory?

You analyze your inventory, pick the right parts, and set up a space for kitting. You train your team and check each kit for quality.

Analyze inventory

Select parts

Train workers

Check quality