Common Materials Used in Car Wire Harnesses

Car wire harnesses use copper, aluminum, PVC, XLPE, nylon, and more for conductivity, flexibility, heat resistance, and cost efficiency in vehicles.

Car wire harnesses use copper, aluminum, PVC, XLPE, nylon, and more for conductivity, flexibility, heat resistance, and cost efficiency in vehicles.

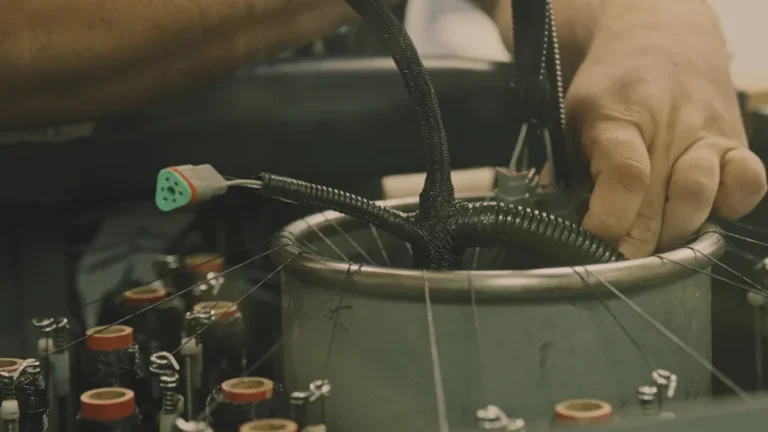

Wire Harness Assembly in automotive manufacturing involves precise steps to ensure safe, reliable connections and compliance with industry standards.

OEM vs aftermarket wire harness: Compare quality, cost, compatibility, and warranty to choose the best option for your vehicle or custom project.

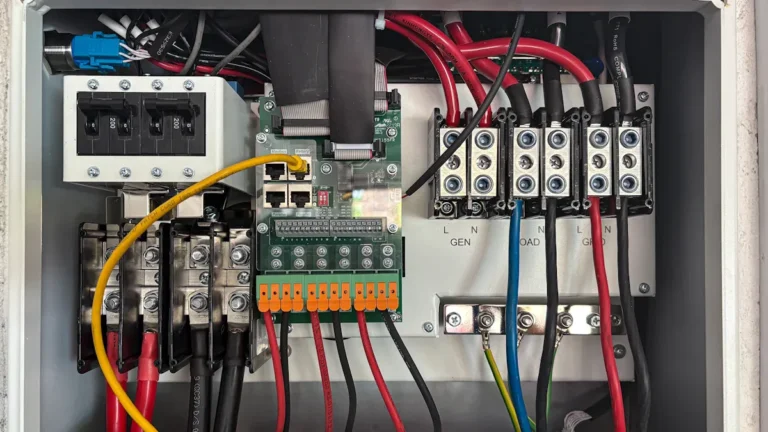

2025 EV wiring harness standards require higher voltage tolerance, improved fire safety, and strict compliance for safer, more reliable electric vehicles.

The global EV wire harness market is set for explosive growth, with forecasts estimating it will reach $23.7 billion by 2025. This article examines key growth drivers, emerging technologies, and region-wise opportunities. Market Drivers Booming…

Discover the step-by-step process of wire harness & cable assembly manufacturing, from design and material prep to assembly and quality testing.

Introduction Solar farms are expanding into deserts, tundras, and other harsh environments. But what happens to the wiring¡ªespecially DC cable harnesses that face daily UV, sand, frost, and mechanical strain for decades? A solar farm…

Compare new energy harness types for automotive and solar use, focusing on efficiency, safety, and sustainability in modern energy systems.

Wiring harness solutions for home appliances organize and protect wires, ensuring safety, reliability, and efficient performance in everyday devices.

An appliance harness organizes and connects wires in home appliances, ensuring safe power and signal transfer for reliable, efficient operation.