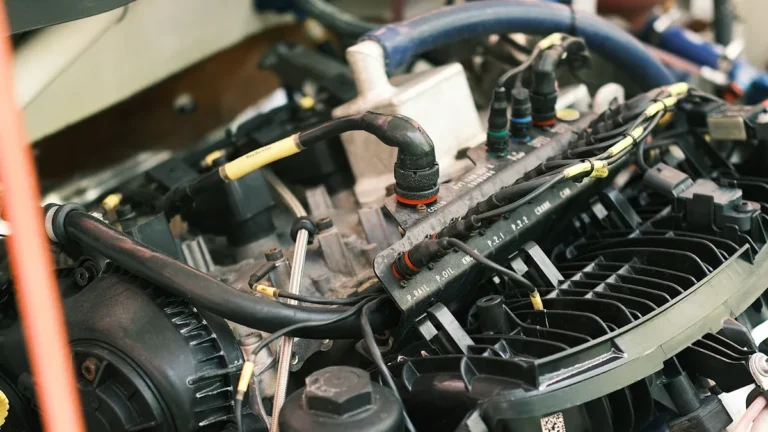

Сертификация ISO/TS16949 в автомобильной промышленности...

Сертификация ISO/TS16949 гарантирует, что производители автомобильных кабелей соблюдают строгие стандарты качества., безопасность, и требования глобальной цепочки поставок для успеха отрасли.