Top 10 Wiring Harness Manufacturers to Watch in 2026

When you choose from the top 10 wiring harness manufacturers in world, you ensure your products achieve the highest standards of safety and reliability. This decision is crucial for automotive, industrial, and everyday consumer applications. The top 10 wiring harness manufacturers in world deliver premium wire harnesses, offer specialized solutions, and provide robust wiring systems. Each certified wire harness manufacturer undergoes rigorous safety and performance testing to meet strict global standards.

Here’s how selecting a manufacturer from the top 10 wiring harness manufacturers in world impacts your products:

Aspect | Impact on Performance and Safety |

|---|---|

Thorough inspections prevent issues and ensure long-term reliability. | |

Customization Capabilities | Tailored designs enhance safety and product dependability. |

Adherence to Standards | Compliance with international regulations guarantees optimal performance. |

By partnering with the top 10 wiring harness manufacturers in world, you benefit from the latest wire harness technologies, comprehensive support, and expert guidance for high-voltage and specialized systems. These leading manufacturers utilize advanced production methods and serve clients worldwide, ensuring exceptional service and innovative solutions.

Key Takeaways

Picking a top wiring harness manufacturer keeps your products safe and reliable.

The wire harness market around the world will get much bigger. It may reach USD 94.8 billion by 2033.

Find manufacturers with good certifications like ISO 9001:2015 to make sure of quality.

Customization choices from manufacturers can make your wiring systems work better.

Choose manufacturers that work in many countries for better help and quicker delivery.

Global Wire Harness Industry Overview

Market Growth and Trends

The global wire harness industry is growing fast. In 2024, the market was worth USD 60.5 billion. Experts think it will reach USD 94.8 billion by 2033. This means the market will grow by 5.3% each year from 2026 to 2033.

Asia-Pacific will be the top region for making and using wire harnesses in 2026. China, India, and Japan help this growth with strong economies and more factories. Europe is also important, with Germany, the United Kingdom, and France leading. These countries care about the environment and have big industries.

You will see some big changes in the market:

The ABS wire harness market will grow by 7.5% each year from 2026 to 2033.

In 2024, the ABS wire harness market was USD 1.2 billion. By 2033, it may reach USD 2.3 billion.

New technology, rules, and changes in the economy cause these trends.

Evidence Description | Source |

|---|---|

Wire harnesses use new materials and better ways to make them. | Wiring a Better Future The Role of Wire Harness Manufacturers |

AI and automation will change wire harnesses in the future. | |

Automation helps factories work faster and more accurately. | |

Lighter materials help cars and planes use less fuel and work better. |

Key Sectors and Applications

The automotive industry uses the most wire harnesses. Electric and hybrid vehicles need good wiring to work well. Aerospace also needs wire harnesses for safe electrical systems. Factories use wire harnesses to help machines work smarter.

Industry | Description |

|---|---|

Automotive | Needs more wire harnesses because of electric and hybrid vehicles. |

Aerospace | Needs safe electrical systems for many uses. |

Industrial | Uses wire harnesses for smart machines and automation. |

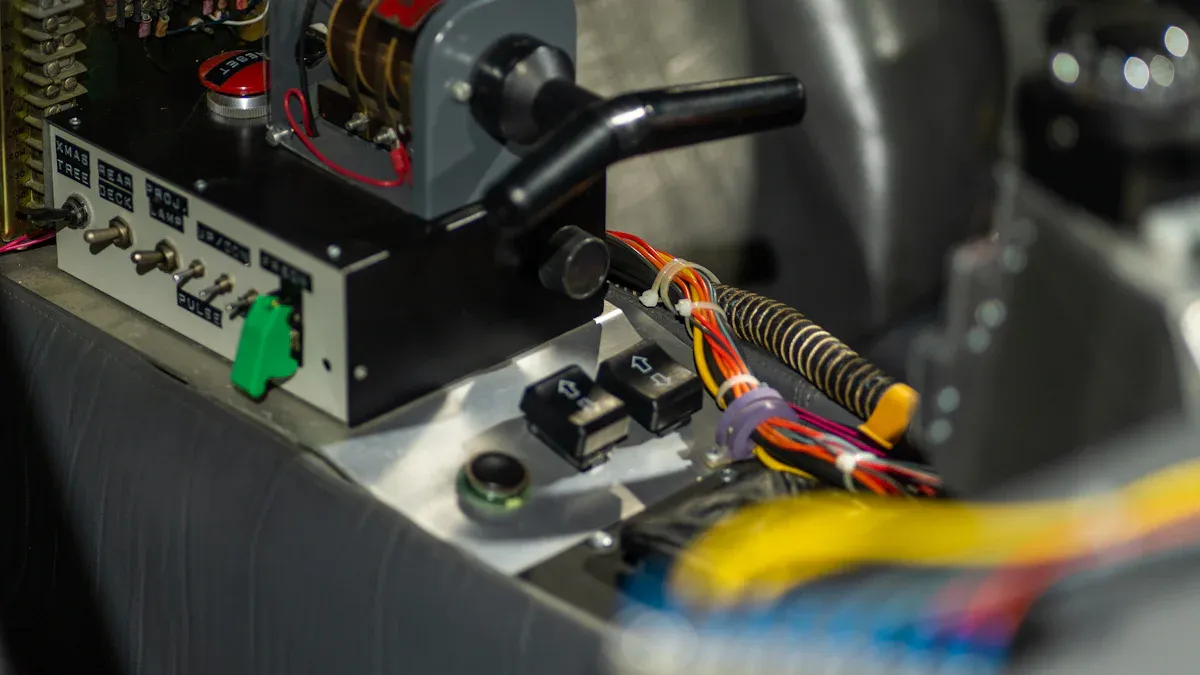

In cars, wire harnesses connect many parts together. They help control engines, lights, and power steering by sending electrical signals.

Tip: Pick a wire harness supplier that uses new ways to make products and understands your industry’s needs.

Criteria for Top 10 Wiring Harness Manufacturers in World

Picking the right wire harness manufacturer helps you get products you can trust. There are three main things to think about: innovation and technology, certifications and quality, and global presence.

Innovation and Technology

You want a manufacturer that comes up with new ideas. Top companies spend money on research to make better products. They use machines to build wire harnesses faster and with fewer errors. Using lightweight materials helps cars and planes save fuel. Some companies use modular designs. This lets them make harnesses for many vehicles and save money. You will find advanced electrical systems and high-voltage harnesses for electric vehicles. These new ideas help meet the needs of the automotive industry.

Criteria | Description |

|---|---|

Market Share | Big market share means the company is skilled and trusted. |

R&D Investment | Spending more on research leads to new and better products. |

Innovative Technologies | New technology helps the industry grow and improve. |

Product Diversity | Many products give you more options to choose from. |

Sustainable Manufacturing Practices | Eco-friendly ways are important for the future of the planet. |

New changes include using AI and IoT. These make wire harnesses smarter and more dependable, especially for cars.

Certifications and Quality

Certifications show that a manufacturer follows strict rules. Look for ISO 9001:2015, IPC/WHMA-A-620, and IATF 16949 for car quality. These certifications mean the company makes safe and good products. Tests like continuity testing, insulation resistance testing, and mechanical testing help make sure products work well.

Certification | Importance |

|---|---|

ISO 9001:2015 | Shows the company has good quality systems. |

AS9100 | Needed for safety and reliability in aerospace. |

IPC/WHMA-A-620 | Sets rules for how wire harnesses should be made. |

Companies that follow these rules can promise high-quality wire harnesses. You get products that last longer and work better.

Global Presence

A strong global presence means you can get products and help anywhere. Top manufacturers have many factories and centers around the world. For example, Yazaki Corporation has 46 locations worldwide. Sumitomo Electric Group makes wire harnesses for 24% of all cars. This helps you get fast delivery and good service.

Tip: Always check if your supplier has places around the world. This helps you get products and support quickly, no matter where you are.

Top 10 Wiring Harness Manufacturers in World 2026

Yazaki Corporation

Yazaki Corporation is one of the biggest wire harness makers. Their products are in many car wire harness systems. Yazaki works on wiring harnesses for cars, trucks, and electric vehicles. The company spends money on smart wire harness assembly and high-voltage systems. Yazaki has factories and technical centers in more than 40 countries. You get help from their global team and quick delivery. Yazaki has ISO 9001 and IATF 16949 certifications. These show their products are safe and high quality. You can count on Yazaki for good wire harnesses and custom cable assembly for cars and the military.

Sumitomo Electric Industries

Sumitomo Electric Industries is a leader in the wire harness market. They use advanced technology and care about the environment. Many car brands use their wire harness products. Sumitomo makes high-voltage wire harnesses for electric and hybrid cars. The company has a network in Asia, Europe, and North America. Sumitomo Electric Industries has important certifications:

ISO 9001

IATF 16949

Their wire harnesses meet strict rules. Sumitomo also helps the military and factories with custom cable assembly and high-voltage solutions.

LEONI AG

LEONI AG is a top wire harness maker from Germany. Their wire harnesses are in many cars. LEONI uses new materials and eco-friendly ways to make wire harnesses. The company has many products and new ideas:

Product Line | Description |

|---|---|

LEONI EcoSense® Nxt | More cable choices |

LEONI EcoSense® Nxt+ | Better charging cables |

LEONI exMW® | New magnet wire |

LEONI Mocar® | Cables for high heat |

LEONI Adascar® | Multi-core cables |

LEONI Dacar® | Data and coaxial cables |

LEONI Hivocar® | High-voltage cables |

LEONI exFC® | Flat cables |

LEONI LIMEVERSE® | Special cable solutions |

LEONI AG helps car, military, and factory clients with custom cable assembly and high-voltage wire harnesses. You get help from their worldwide team and good customer service.

Aptiv PLC

Aptiv PLC is a leader in making wire harnesses for cars and the military. Their wire harnesses are in electric vehicles and smart cars. Aptiv uses new technology to make wire harnesses lighter and better. Their special ideas include:

Advancement | Description |

|---|---|

Aluminum Cabling | Makes wiring lighter for electric vehicles. |

Velocity Tool Suite | Picks the best wire size with computer models. |

Flat Busbars | Uses flat wires to save space and improve power flow. |

Aptiv has ISO 9001 and IATF 16949 certifications. You get good wire harnesses and custom cable assembly for high-voltage and military needs.

TE Connectivity

TE Connectivity is a global wire harness maker known for new ideas and quality. Their wire harnesses are in many cars and machines. TE Connectivity makes high-voltage wire harnesses for electric vehicles and military gear. The company has factories in over 50 countries. TE Connectivity has ISO 9001, IATF 16949, and IPC/WHMA-A-620 certifications. You get good customer service and quick wire harness production.

Furukawa Electric

Furukawa Electric is a trusted wire harness maker from Japan. Their wire harnesses are in many car brands. Furukawa Electric works on high-voltage wire harnesses and uses eco-friendly materials. The company helps car, military, and factory clients with custom cable assembly. Furukawa Electric has ISO 9001 and IATF 16949 certifications. You get good wire harnesses and strong technical help.

Lear Corporation

Lear Corporation is a top wire harness maker for cars. Their wire harnesses are in many cars around the world. Lear works on smart wire harnesses and high-voltage solutions for electric vehicles. The company has a worldwide network and makes custom cable assembly for cars and the military. Lear Corporation has ISO 9001 and IATF 16949 certifications. You get fast wire harness production and good customer service.

Yueqing Chengli Electronic Technology Co., Ltd.

Yueqing Chengli Electronic Technology Co., Ltd. is a top wire harness maker in China. Their wire harnesses are in cars, home appliances, and new energy systems. Yueqing Chengli has many products:

Car wiring harnesses for cars and trucks

Appliance harnesses for home and factory machines

New energy harnesses for electric vehicles and green energy

Connectors for safe electrical connections

Electric wire & cable for good power flow and safety

Yueqing Chengli uses eco-friendly materials that meet EU rules. The company has CE, UL, IATF 16949, and ISO 9001 certifications. Their wire harnesses are in products from brands like Haier, Hisense, Panasonic, and Xiaomi. Yueqing Chengli makes custom cable assembly and high-voltage wire harnesses for cars and the military. You get good customer service and quick delivery.

Tip: Yueqing Chengli lets you ask for custom car wire harnesses and automotive wiring harnesses. You can get designs that fit what you need.

Molex

Molex is a global wire harness maker known for new ideas. Their wire harnesses are in cars, computers, and military gear. Molex works on high-voltage wire harnesses and smart ways to make them. The company has ISO 9001, IATF 16949, and IPC/WHMA-A-620 certifications. Molex makes custom cable assembly and quick wire harnesses for cars and the military.

DRÄXLMAIER Group

DRÄXLMAIER Group is a top wire harness maker from Germany. Their wire harnesses are in luxury cars. DRÄXLMAIER works on high-voltage wire harnesses and smart ways to make them for electric vehicles. The company makes custom cable assembly and wire harnesses for cars and the military. DRÄXLMAIER has ISO 9001 and IATF 16949 certifications. You get help from their worldwide team and good customer service.

Note: If you pick a wire harness maker from this list, you get new technology, good wire harnesses, and strong help for cars, the military, and high-voltage uses.

Automotive Wire Harness Innovations

Smart Manufacturing

Big changes are happening in how wire harnesses are made. Smart manufacturing uses robots and machines to build wire harnesses. These robots work with high accuracy. Nissan and the University of Tennessee started a project in July 2024. They wanted to automate the wiring harness assembly process. Students helped robots put wires into connectors. Their system proved robots can assemble wire harnesses very well. This new way solves one of the last manual steps in car making. You get faster production and better quality. Local automation makes shipping easier and gives companies more choices.

Robots now put wires into connectors with great accuracy.

Automation makes production faster and keeps quality steady.

Student ideas helped make wire harness assembly much better.

Smart manufacturing helps you get car wire harnesses quickly and with fewer errors.

Sustainable Materials

You help the planet when you pick wire harnesses made with sustainable materials. These materials can be recycled or break down naturally. Using them cuts down on waste and supports global rules for sustainability. Companies want to look good and keep customers happy. Sustainable materials also make wire harnesses work better. You see less harm to the planet and better results in your car projects.

Benefit | Description |

|---|---|

Less Waste | Recyclable materials mean less trash in landfills. |

Better Performance | Eco-friendly choices meet high standards. |

Brand Reputation | Sustainability brings in more customers. |

Customization Trends

You see more options in wire harness designs for cars. The industry now focuses on making custom wire harnesses for new needs. Hybrid and electric cars need special wire harnesses for high-voltage systems. Driver assistance systems need complex wiring for smooth communication. Connected cars and infotainment systems need strong wires for sending data. Lighter materials and smart designs help cars work better and pollute less.

Hybrid and electric cars need special wire harnesses.

Driver assistance systems need detailed wiring solutions.

Connected cars need strong wires for safety and entertainment.

Lighter designs help cars use less fuel and pollute less.

Customization lets you choose car wire harnesses that fit your needs exactly.

How to Choose a Wire Harness Manufacturer

Picking the right wire harness manufacturer keeps your products safe. You should check for certifications, custom options, support, cost, and value. These steps help you make smart choices for your project or business.

Assessing Certifications

Certifications mean a manufacturer follows strict quality rules. Look for ISO 9001:2015, UL, CE, RoHS, REACH, and IATF16949. These show the company meets global standards and works to get better. Testing is also important. Good manufacturers test every wire harness with different methods. They use continuity, pull test, hipot, resistance, and full-function testing.

Certification | Importance |

|---|---|

ISO 9001:2015 | Shows high quality and that the company keeps improving products and service |

Required testing includes:

Continuity

Pull test

Hipot

Resistance

Full-function testing

Tip: Always ask to see proof of certifications before you buy. This helps you avoid safety and performance problems.

Evaluating Customization and Support

You need wire harnesses that match your needs. Find manufacturers who offer custom wire harness and special solutions. These companies listen to what you want and design products for you. Good support means you get help with design, setup, and after-sales service. If you work with cars, ask about passenger car solutions and custom wire harness choices. Fast answers and technical help make your project easier.

Choose manufacturers who offer:

Custom wire harness design

Special solutions for your needs

Technical help and quick replies

Note: Good support helps you fix problems fast and keeps your project moving.

Comparing Cost and Value

You want the most for your money. Compare costs by looking at materials, labor, design, and technology. Some companies use new ways to make products cheaper. Making lots of wire harnesses at once can lower the price. Make sure the company still meets safety and quality rules, even if the price is low.

Factor | Description |

|---|---|

Cable Material Costs | The price of copper and aluminum changes with demand and mining. |

Labor and Manufacturing | Labor costs depend on where the factory is and how much is automated. |

Design and Customization | Special and complex wire harnesses cost more to make. |

Technological Integration | Extra features make products more complex and expensive. |

Economies of Scale | Big orders make each wire harness cost less. |

Regulatory Compliance | Meeting safety and quality rules adds to the cost. |

Tip: Get quotes from a few manufacturers. Compare what you get for the price, not just the cheapest offer.

You can find many good things about the top 10 wire harness manufacturers. Each company is a leader because they have new ideas, strong quality, and help people all over the world. The table below shows what makes each company special in the industry:

Manufacturer | Strengths and Innovations |

|---|---|

Yazaki | Leader in automotive wiring harnesses, strong R&D and sales |

Leoni | Global supplier, focus on energy data management |

Aptiv | Active safety, autonomous driving, connected services |

Sumitomo Denso | Strong wire manufacturing, global reach |

Lear | Tier 1 supplier, covers all major markets |

Furukawa Electric | Wide range in automotive and electronics manufacturing |

Dekesmir | Composite wiring harness systems for top automakers |

Luxshare Precision | Technology-driven, rapid growth |

Fujikura | Optical cable technology, connection solutions |

SAISONIC | Intelligent manufacturing, strict quality standards |

When you pick a partner, look for new ideas, good quality, and strong support. Use the tips and trends in this guide to help you choose well. Keep learning about new ways to make wire harnesses for success in the future.

FAQ

What is a wiring harness?

A wiring harness is a bunch of wires tied together. It connects electrical parts in cars, machines, or appliances. It keeps wires neat and safe when making and using things.

Why do certifications matter when choosing a wire harness manufacturer?

Certifications prove a manufacturer follows important rules. They help you know the wiring harnesses are safe and good quality.

How does automation improve wiring harness manufacturing?

Automation means machines build wiring harnesses instead of people. This makes production faster and has fewer mistakes. The quality of the harnesses gets better too. Many companies use automation now.

Can I get a custom wiring harness for my project?

Yes, you can order a custom wiring harness. Manufacturers will help you design one that fits your needs. This makes your project easier to finish.

What industries use wiring harnesses the most?

Wiring harnesses are used in cars, home appliances, and factories. They help connect and power many things in different industries.