Wire Harness Assembly Process in Automotive Manufacturing

Wire harness assembly in automotive manufacturing starts with careful planning and precise execution. Engineers design each wiring harness to connect vital systems throughout the vehicle. Modern cars often include around 40 split wire harnesses, each containing up to 3,000 wires and 700 connectors. These assemblies manage functions for the engine, chassis, doors, dashboard, and more. The wire harness assembly process demands accuracy at every step. Automotive wiring harnesses ensure reliable power and signal flow, supporting advanced features and safety. Technicians use organized layouts and tested methods to complete the manufacturing process, keeping each wiring harness consistent and dependable.

Key Takeaways

Wire harness assembly starts with detailed design and planning to ensure safe, reliable connections throughout the vehicle.

Advanced simulations and precise cutting, stripping, and crimping improve quality and reduce errors in the manufacturing process.

Proper routing, bundling, and protective coverings keep wires safe from damage and interference, boosting harness durability.

Automation speeds up production and reduces mistakes, but skilled workers remain essential for complex and custom tasks.

Thorough testing, inspection, and clear labeling guarantee each wiring harness meets safety standards and performs well in vehicles.

Wire Harness Assembly Process

Schematic Design

Engineers begin the wire harness assembly process by creating detailed schematic diagrams. These diagrams use specialized CAD wiring software to show how each wire connects different components. Schematic diagrams focus on how circuits work, not just where wires go. Industry standards require careful selection of wire gauge, length, and color coding. Connectors must match electrical and mechanical needs, making it easier to source and review parts. Routing plans help avoid electromagnetic interference by separating wires based on signal type or voltage. Strain relief features, such as cable clamps and grommets, prevent damage from mechanical stress. Outer jackets protect against heat, moisture, and chemicals. Documentation is essential for global manufacturing, troubleshooting, and compliance. The Vehicle Electric Container (VEC) standard helps engineers exchange and archive wiring harness information, supporting collaboration and traceability throughout the vehicle’s life.

Tip: Following industry standards during schematic design ensures safety, reliability, and easier maintenance.

Simulation and Analysis

Simulation and analysis play a key role in the wire harness assembly process. Computer-Aided Engineering (CAE) tools help engineers find weak points and predict how long a harness will last. These tools use X-ray CT imaging to visualize wire shapes and spot damage-prone areas. Early-stage simulation helps control failure modes and improve harness quality before building physical prototypes. Electrical, thermal, and EMI simulations check for voltage drops, hot spots, and electromagnetic interference. Vibration and stress simulations test how well the harness stands up to shaking and bending. These steps reduce prototyping time, catch design flaws early, and make sure the harness meets industry standards. Simulation helps ensure the wiring harness will work reliably in real-world conditions.

Simulation Type | Purpose and Benefits |

|---|---|

Electrical Simulation | Detects undervoltage and overcurrent risks, optimizes conductor sizing, ensures voltage drop limits |

Thermal Simulation | Predicts hot spots, models heat dissipation, guides material selection for high-temperature zones |

EMI Simulation | Simulates electromagnetic interference, validates shielding effectiveness, ensures circuit performance |

Vibration & Stress Simulation | Evaluates mechanical integrity under vibration, simulates flexing and fatigue resistance, enhances durability |

Multiphysics & CFD Modeling | Integrates thermal, electrical, and structural analyses; improves cooling and airflow management |

Wire Cutting and Stripping

The next step in the wire harness assembly process is wire cutting and stripping. Automated machines cut wires to precise lengths and strip insulation without damaging the conductors. These machines handle many wire sizes and types, including complex cables. Accessories like pre-feeders keep wire tension steady, while marking systems and stackers boost efficiency. Precision is vital, especially for small wires. Machines often adjust stripping depth automatically, reducing errors and manual work. Regular blade maintenance ensures clean cuts. In some cases, workers cut and strip wires by hand for custom jobs. The right balance of automation and skilled labor keeps the manufacturing process fast and accurate.

Used for custom or low-volume jobs.

Workers match wire gauge to the correct tool, cut, and carefully remove insulation.

Automated Cutting and Stripping:

Preferred in automotive manufacturing for speed and precision.

Machines handle thousands of wires per hour with minimal errors.

Cutting Styles:

Full Strip: Removes all insulation for crimping or soldering.

Partial Strip: Leaves some insulation to protect conductors.

Blunt Cut: Cuts wire to length without stripping.

Crimping and Termination

Crimping and termination are critical steps in the wire harness assembly process. Workers or machines attach terminals to the ends of wires by compressing them with precise force. This step ensures a strong electrical and mechanical connection. Crimping errors can cause open or short circuits, leading to major failures. Automotive manufacturers use force-displacement curve analyzers and laser micrometers to monitor crimp quality. Improved tooling and monitoring can reduce rework rates from 5% to as low as 0.5%. Crimp height tolerance is usually ±0.05mm. Semi-automatic crimpers and 100% crimp height monitoring help lower field failure rates and warranty costs. Accurate crimping is much more cost-effective than solder joints and is essential for reliable wiring harnesses.

Aspect | Typical Error/Defect Rate or Metric | Notes/Context |

|---|---|---|

Initial rework rate | ~5% | Can be reduced to 0.5% with improved tooling and monitoring |

Variation in crimp profile | 5-8% | Detected before defects occur using force-displacement curve analyzer |

Automotive harness rework rate | Reduced from 12-15% to under 3% | Achieved with optimized processes |

Crimping defects contribution | 38% of electrical failures | Includes under-compressed barrels and over-compressed strands |

Field failure reduction | 55% | Using 100% crimp height monitoring via laser micrometers |

Crimp height tolerance | ±0.05mm | Most reliable crimps occur within this range |

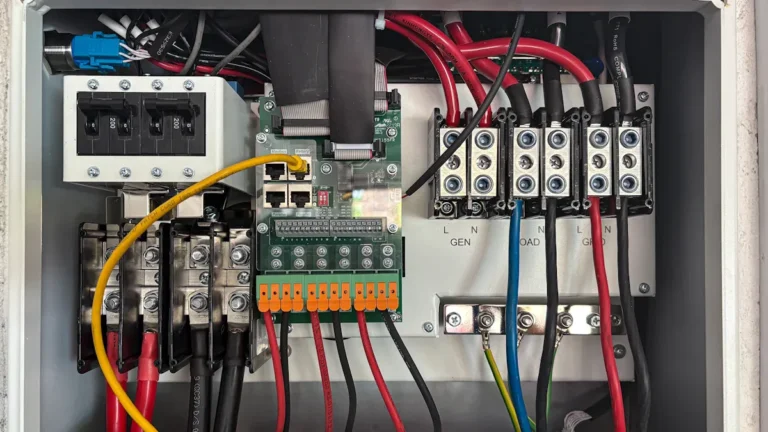

Connector Assembly

Connector assembly joins wires to connectors, allowing easy connection and disconnection in the vehicle. The most common connectors in automotive wiring harnesses include Metri-Pack, AMP Superseal, Anderson, and Weather Pack connectors. Each type offers specific benefits, such as waterproofing or high power capacity. Connectors are classified by their function, such as inline, box, PCB mount, or terminal connectors. Proper connector assembly ensures reliable performance and makes future repairs easier. Choosing the right connector type is vital for the harness assembly to meet automotive standards.

Connector Type | Key Features and Usage |

|---|---|

Metri-Pack Connectors | Excellent sealing and heat performance |

AMP Superseal Connectors | Ideal for hostile environments |

Anderson Connectors | High power capacity and reliability |

Weather Pack Connectors | Weather-resistant and fully waterproof |

Routing and Bundling

Routing and bundling organize wires within the harness assembly. Workers separate power cables from signal cables to prevent electromagnetic interference. Twisted-pair and shielded wires protect signal integrity. Wires near heat sources use thick insulation or heat-resistant coverings. Cable ties and retaining clips keep wires secure and prevent movement or damage. Protective layers, such as corrugated tubes or braided sleeves, guard against moisture and abrasion. Bundling wires into a single loom simplifies installation and boosts protection. Choosing accessible routing paths helps with future repairs and maintenance.

Note: Careful routing and bundling reduce errors, speed up installation, and improve the reliability of the wiring harness.

Protective Coverings

Protective coverings shield the wiring harness from heat, moisture, chemicals, and abrasion. Heat shrink tubing is popular for its low cost, easy use, and strong protection. Braided expandable sleeving offers abrasion resistance and allows heat and moisture to escape. Polypropylene corrugated conduit withstands high temperatures, making it suitable for engine areas. Fiberglass sleeves provide extreme heat resistance. Polyester sleeving stays flexible in cold conditions and resists repeated bending. Tapes with various backings add extra protection, sound dampening, and water resistance. The choice of covering depends on the harness location and environmental risks.

Material / Type | Advantages | Typical Applications |

|---|---|---|

Polypropylene (PP) | High flame retardancy, high melting point, prevents sparking fires, withstands extreme engine temperatures | Engine cable assemblies, embedding into walls, under-floor wiring |

Polyethylene (PE) | Tight seal against liquids and chemicals, electrical and thermal insulation | Wire insulation and sealing in harsh environments |

Polyamide (PA) / Nylon | Impact and abrasion resistance, flexible, corrosion resistant | Vehicle harnesses, hydraulic hoses |

Polyester Monofilament and Multifilament | High wear resistance, flexibility, repeated flexing without damage | Sleeving for wire bundles |

Polyethylene Terephthalate (PET) | Flame retardant, wear resistant, high temperature resistance | Braided wraps for high-temp protection |

Fiberglass | Extremely high temperature resistance, self-extinguishing, high voltage resistance | Motor peripherals, generators |

Tapes (various backings) | Versatile, economical, abrasion and heat resistance, flexibility, sound dampening, water resistance | Bundling, protective wrapping, sealing |

Labeling and Marking

Labeling and marking are the final steps in the wire harness assembly process. Proper labeling ensures correct installation and makes maintenance easier. Automated labeling systems reduce human error and boost efficiency. Labels can be heat-shrink tubing, peel-and-stick, or rotating types, all designed to withstand harsh automotive environments. Labels may be applied before or after wire termination, offering flexibility. Software-driven systems print variable data and barcodes, avoiding manual entry mistakes. Accurate labeling helps technicians identify wires quickly during repairs, reducing downtime and costly errors.

Proper labeling ensures correct installation and high performance.

Automated systems improve accuracy and efficiency.

Durable labels withstand heat, moisture, and chemicals.

Accurate marking speeds up troubleshooting and repair.

Reminder: Inadequate labeling can lead to costly repairs and longer downtime. Clear identification supports fast, reliable service.

Automotive Wiring Harnesses: Technologies

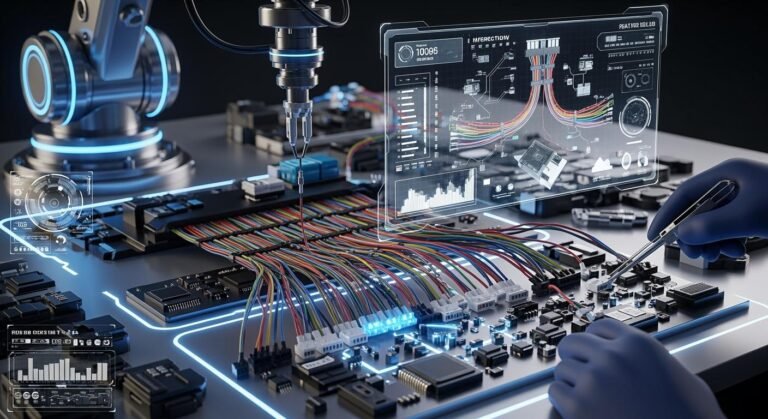

Automation in Assembly

Automotive wiring harnesses have seen major changes with the rise of automation. Factories now use robotic wire handling, automated wire processing machines, and digital twin technology. These systems help reduce human error and improve the quality of each wiring harness. Automation speeds up production and lowers labor costs. Robots handle repetitive tasks like cutting, stripping, and routing wires. Advanced taping processes and ultrasonic welding increase precision and durability. Some factories even use AI and robotics to create smart, autonomous assembly lines near automotive plants. This reduces shipping time and helps meet high demand for electric and hybrid vehicles. Automation also makes work safer by taking over dangerous jobs.

Note: Automation improves efficiency, but high setup costs and frequent design changes can make full automation difficult.

Manual Labor and Skilled Work

Even with new technology, most automotive wiring harnesses still rely on skilled workers. About 90% of assembly tasks are done by hand. Workers handle complex wiring, connect terminals, and check for quality. Flexible cables and many different parts make it hard for robots to do every job. Skilled technicians adjust harnesses for custom designs and fix problems quickly. Manual labor remains important for tasks that need careful attention and flexibility.

Use of Formboards

Formboards play a key role in wiring harness assembly. Workers use these boards as templates to lay out wires and connectors in the correct shape and order. Merged formboards let factories build several similar harnesses on one line, saving space and time. They also help manage changes and reduce mistakes. Tools like Capital Formboard Manager automate board setup and keep track of fixture positions. Formboards help balance workloads, speed up setup, and improve operator efficiency.

Formboards allow quick changes for different harness types.

They help reduce setup times and errors.

Operators can produce small or custom harnesses without extra equipment.

Tools and Equipment

Specialized tools ensure high-quality automotive wiring harnesses. Workers use wire strippers and cutters for clean wire preparation. Crimping tools make strong connections between wires and terminals. Soldering stations and ultrasonic welding machines create secure bonds. Testing equipment checks for electrical safety and performance. Assembly boards and labeling machines help keep the process organized. The table below shows some key tools and their roles:

Tool/Equipment | Purpose/Role |

|---|---|

Wire Stripping Machines | Remove insulation without damaging wires |

Crimping Machines | Attach wires to terminals with high precision |

Ultrasonic Welding Machines | Fuse wires for strong, defect-free connections |

Terminal Insertion Tools | Insert terminals into connectors accurately |

Testing Equipment | Check for electrical safety and performance |

Assembly Boards | Provide templates for precise harness layout |

Quality and Testing in Wiring Harness

Electrical Testing

Automotive manufacturers use several types of electrical testing to ensure every wire harness works safely and reliably. Testing each connection helps find problems like mis-wiring, loose joints, or short circuits. Technicians use machines to check for continuity, resistance, and insulation quality. They also perform high-voltage tests to make sure insulation can handle strong currents without leaking. Functional testing checks if components like relays and sensors respond as expected. The table below shows common tests and their purposes:

Test Type | Purpose |

|---|---|

Continuity Testing | Finds mis-wiring and loose connections |

Resistance Measurement | Measures wire resistance for accuracy |

Short Circuit Testing | Detects crossed wires and unwanted connections |

High Voltage Insulation Testing | Checks insulation strength and safety |

Functional Testing | Verifies correct operation of active components |

These steps in quality control and testing help prevent hazards such as overheating or fires.

Inspection and Approval

After testing, each wire harness goes through a quality inspection. Inspectors look for defects like damaged insulation, poor crimps, or missing labels. They check that all wires and connectors match the design and meet industry standards. Some of the most important standards include SAE, UL, and ISO, which focus on safety, reliability, and environmental compliance. Many manufacturers also follow IATF 16949, which requires strict process control and traceability. Inspectors use checklists and visual aids to make sure every harness passes before approval. This careful process ensures that only high-quality harnesses move forward.

Tip: Quality inspection at this stage helps catch small issues before they become big problems in the vehicle.

Packing and Shipping

Proper packing and shipping protect wire harnesses from damage during transport. Manufacturers use special containers with smooth sides and rounded corners to prevent harm to cables and connectors. Many containers include dividers, textile dunnage, or ESD materials to guard against movement and static electricity. Stackable and nestable designs save space and keep harnesses safe. Durable packaging ensures that harnesses arrive at the next assembly point in perfect condition. Careful shipping logistics help maintain product quality and reduce delays.

Engineering and Customization

Material Selection

Material selection shapes the performance and reliability of every automotive wiring harness. Engineers often choose copper for its high electrical conductivity, flexibility, and durability. Copper helps ensure strong electrical performance and long service life. Some automotive harnesses use aluminum to reduce weight and cost, but it does not conduct electricity as well as copper. Insulation materials like XLPE, silicone rubber, and thermoplastic elastomers protect wires from heat and electrical stress, especially in electric vehicles. Protective sheathing, such as silicone, polyurethane, and PVC, shields the harness from heat, abrasion, and chemicals. The right combination of materials allows standard and customized wiring harnesses to withstand harsh automotive environments.

Note: Material choice balances cost, durability, and compliance with automotive standards.

Custom Designs for Automotive

Custom wiring harness solutions address the unique needs of each vehicle. Engineers start by defining project requirements based on vehicle type, function, and environment. They create detailed wiring diagrams to map out components and routing. Material selection focuses on durability and resistance to heat, moisture, and vibration. Prototyping helps test fit and function, revealing any design issues early. Comprehensive testing checks for electrical continuity and insulation strength. Documentation ensures that the final product meets all specifications. Custom harnesses optimize space, improve durability, and enhance performance for modern vehicles with complex electrical systems.

Key steps in custom harness design:

Create detailed diagrams for wiring and routing.

Select materials for durability and resistance.

Prototype and test for fit and function.

Conduct thorough electrical and environmental tests.

Document the design for quality control.

Schematic Layouts

Wiring harness design requires careful schematic layouts. Engineers face challenges as automotive wiring systems grow more complex. They use advanced CAD tools to translate 2D diagrams into 3D vehicle structures. Each wire must be sized for its electrical load and grounded properly. Designers plan wire bundles with the right paths and attachment points to avoid damage or interference. They flatten 3D designs into 2D drawings for manufacturing, which takes time and skill. Meeting network requirements, such as CAN bus length, can force creative routing. Consistent labeling and color-coding help with installation and maintenance.

Engineering Consideration | Explanation |

|---|---|

Weight | Reducing harness weight improves speed and fuel efficiency. |

Construction/Material | Materials must meet standards; copper and aluminum are common choices. |

Durability | Harnesses must resist heat, moisture, and vibration. |

Safety | Proper protection and testing prevent failures and fire risks. |

Design/Layout | Good routing and labeling make installation and repair easier. |

The wire harness assembly process combines careful design, advanced technology, and skilled work to create reliable automotive wiring systems. Quality control, guided by strict industry standards and advanced testing, ensures each harness performs safely. Looking ahead, new trends shape the industry:

AI and machine learning for smarter layouts

Modular designs for easier assembly and repair

These changes help the process stay flexible, safe, and ready for future automotive needs.

FAQ

What is a wire harness in a car?

A wire harness is a group of wires, connectors, and terminals. It carries electrical power and signals to different parts of a vehicle. This system helps control lights, sensors, and other electronic features.

Why does accuracy matter in wire harness assembly?

Accuracy keeps the wiring harness safe and reliable. Mistakes can cause short circuits, system failures, or even fires. Careful assembly helps every part work as designed.

How do manufacturers test wire harnesses?

Manufacturers use machines to check for correct wiring, strong connections, and insulation quality. They perform tests like continuity, resistance, and high-voltage checks. These steps help find problems before the harness goes into a vehicle.

Can wire harnesses be customized for each vehicle?

Yes, engineers design custom wire harnesses for different vehicles. They choose materials, layouts, and connectors based on the car’s needs. Custom harnesses improve performance and fit special features.

What materials protect wire harnesses from damage?

Manufacturers use materials like heat shrink tubing, braided sleeving, and special tapes. These coverings protect wires from heat, moisture, and abrasion. The right material depends on where the harness will be used.