ワイヤーハーネスとケーブルアセンブリの製造方法

The process of wire harness & cable assembly manufacturing involves many steps. Each step, such as selecting materials and assembling components, requires careful attention. Custom harnesses frequently utilize advanced tools like robots and 3D models to enhance accuracy. These tools contribute to improved product quality and reduce labor costs. Research indicates that optimizing these steps can increase daily production by 31.95% and decrease costs by 19.73%. This highlights the significance of precision and quality in the production of robust wire harnesses.

重要なポイント

Planning and testing are important to make good wire harnesses. Working with customers helps avoid errors and makes production faster.

Picking the right materials is key for strong products. Think about how well they conduct electricity, stretch, and handle heat.

Using machines to cut and strip wires makes work precise. This improves quality and speeds up making the wire harnesses.

Checking quality is very important. Regular tests make sure wire harnesses are safe and follow rules, avoiding big problems later.

Packing and labeling carefully keeps wire harnesses safe during shipping. Staying organized makes delivery easier and faster.

Design and Prototyping in Wire Harness Manufacturing

Design and prototyping are key steps in making wire harnesses. These steps help ensure the product fits your needs and works well. By working together, using drawings, and testing prototypes, manufacturers can avoid mistakes and work faster.

Working with customers to set requirements

The first step is to understand what you need. Manufacturers often use teamwork methods like the Flexible Integrated Team (FIT) approach. This creates a group focused on your project. It ensures details like wire length and connector type match your needs.

Another method is the Orchestrated Customer Engagement (OCE) model. This uses data and analytics to give a custom experience. These methods help set clear requirements, reduce mistakes, and make sure the product works as planned.

Making schematics and technical drawings

After knowing your needs, manufacturers create detailed drawings. These drawings guide the wire harness assembly process. Tools like Altium Designer and RapidHarness help make accurate designs. 例えば, Altium Designer can import drawings, create layouts, and add symbols.

Other tools like Microsoft Visio and Lucidchart make designing easier. They help show complex setups clearly. These tools ensure every wire and connector is included, reducing errors and speeding up production.

Testing with prototypes

Prototyping is important to test the design before production. Virtual prototypes can find problems early by simulating real-world conditions. This can lower defect rates by up to 60% in some cases.

Advanced methods like Monte Carlo simulations predict how the product will perform. High-performance computers help test designs faster. This ensures the product meets quality standards and market needs.

Prototyping also allows for changes if needed. This step ensures the final wire harness is reliable and fits your requirements.

Material Preparation for Wire Harness Assembly

Getting materials ready is an important part of making wire harnesses. It makes sure the right parts are chosen, meet rules, and are set up for smooth production. Good preparation affects how strong and long-lasting the wire harness will be.

Picking wires, コネクタ, and terminals

Choosing the right parts is key for a strong wire harness. You need wires, コネクタ, and terminals that fit your project needs. Things like tensile strength show how much stress a material can handle. 例えば, strong wires can handle heavy loads, and tough connectors last longer without wearing out.

When picking materials, think about these features:

Conductivity: Helps electricity flow easily.

Elasticity: Handles vibrations to keep connections safe.

Wear Resistance: Keeps parts working well for a long time.

温度抵抗: Works in hot or cold conditions.

Corrosion Resistance: Stops damage in tough environments.

These features make sure the wire harness works well for its job.

Making sure materials follow rules

Following rules is very important in wire harness making. Rules make sure materials are safe, strong, and work with other parts. 例えば, terminal connectors must meet ul 1977 in the U.S. and IEC 61984:2008 worldwide. Below is a table of common rules:

Type of Component | Compliance Standards |

|---|---|

Terminal Connectors | U.S. – UL 1977, Canada – CSA C22.2 No. 182.3-16, 欧州連合, 中国, ブラジル, India – IEC 61984:2008 |

Electrical Quick-Connect Terminals | U.S. – UL 310, Canada – CSA C22.2 No. 153-14 |

Terminal Blocks | U.S. – ul 1059, Canada – CSA C22.2 No. 158, ANSI/UL 60947-7-1, -2, -3, -4, で 60947-1, -2, -3, -4 |

Cable Assemblies | U.S. — UL 1682, ul 2238, ul 2237, Canada CSA C22.2 No. 182.1, CSA C22.2 No. 182.3 |

Following these rules makes products safer, more stable, and better. This helps the wire harness meet what customers want.

Setting up materials for easy production

Organizing materials well helps production run smoothly. Plans like Material Requirements Planning (MRP) and Just-In-Time (ジット) save time and cut waste. MRP makes sure you have all parts when needed. JIT orders parts only when required, lowering storage costs. Together, they improve how resources are used.

Good planning also avoids running out of parts and shortens wait times. This helps deliver products on time and saves money. By organizing materials well, you can work faster and make better wire harnesses.

Cutting and Stripping in the Wire Harness Manufacturing Process

Cutting and stripping wires are important steps in making wire harnesses. These steps prepare wires to exact sizes for strong electrical connections.

Cutting wires and cables to exact lengths

Wires must be cut to the right length for the design. Automated tools help cut wires with great accuracy. 例えば, aerospace companies use advanced machines for strict standards. Automation improves precision and makes sure results are consistent. Tools like Alicona 3D measurement systems prevent mistakes and give clear measurements. This ensures wires fit perfectly into the harness.

Stripping insulation to uncover conductors

Stripping insulation removes the outer layer to show the conductor. Automated systems make this step more accurate and reduce errors. 例えば:

Height detection errors are just 3.2%.

These systems protect the conductor from damage during stripping. Damaged conductors can cause heat, noise, or failure. Knowing wire thickness and insulation type helps ensure safe connections.

Using automated tools for better results

Automation has improved cutting and stripping wires. Automated tools save time and improve quality control. They cut and strip wires with consistent accuracy, avoiding human mistakes. This keeps the final product reliable. Adding automation to production increases efficiency and quality.

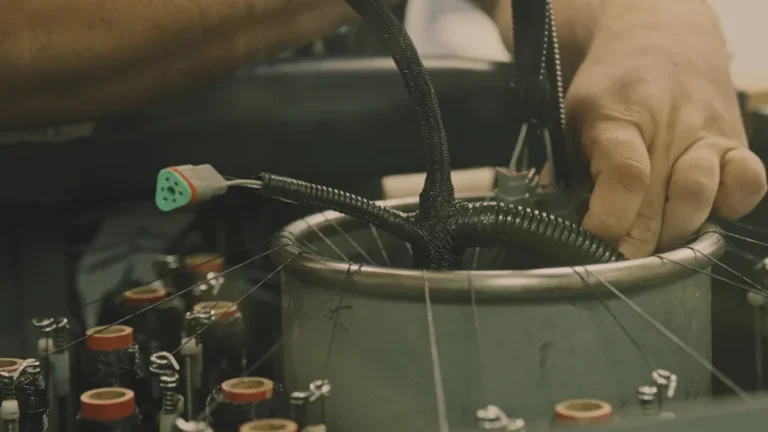

Wire Harness Assembly and Termination

Organizing wires and cables using diagrams

Organizing wires based on diagrams ensures the harness matches the design. Follow the layout in the drawings to arrange cables neatly. This step improves safety by lowering risks like electrical shorts. It also makes the harness look better and easier to fix later. Proper organization helps wires stay connected and power flow smoothly.

To do this, methods like routing, overmolding, and labeling are used. Routing plans how wires connect devices and keeps them tidy. Overmolding protects cables by covering them with strong materials. Labeling and color-coding make wires easy to identify for repairs. Testing the setup is important too. Continuity tests check connections to ensure no wires are damaged or misplaced.

Adding connectors, 端子, and protective covers

Adding connectors and terminals is an important part of making harnesses. These parts are attached to create strong electrical connections. Good attachment prevents wear and tear, making the harness last longer. It also reduces risks like overheating or short circuits, keeping it safe. For high-frequency uses, this step improves efficiency by lowering signal loss.

Protective covers keep wires safe from things like heat, water, and damage. Using strong materials for connectors and covers helps the harness work well in tough conditions. Testing ensures the connections are secure and meet quality standards. This step ensures the harness works reliably without problems.

Securing parts with ties, clamps, or sleeves

Ties, clamps, and sleeves keep the harness organized and steady. Ties bundle wires together to stop them from tangling or moving. Clamps hold cables tightly, reducing stress on connections. Sleeves add extra protection, guarding wires from damage and wear.

This step keeps the harness strong and working properly. It stops wires from shifting, which could cause breaks or issues. Testing checks that all parts are fastened securely. By securing everything well, the harness becomes durable and meets industry rules.

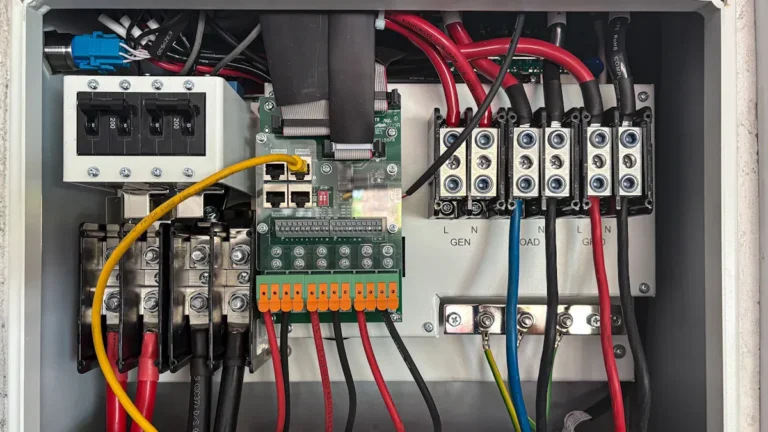

Quality Control and Testing in Wire Harness Manufacturing

Quality control and testing are very important in making wire harnesses. These steps make sure the products are safe, work well, and meet strict rules. By checking for problems, running tests, and following industry standards, manufacturers can ensure reliable wire harnesses.

Checking for problems and mistakes

Checking for problems is the first step to ensure quality. Finding issues early stops bad products from reaching customers. New tools like real-time monitors そして non-destructive tests help a lot. 例えば, the Surface Inspector SI3100 finds tiny flaws quickly, keeping quality consistent.

Standard rules for inspections are also very helpful. They make sure everyone checks for problems the same way. A typical inspection process includes:

Checking Materials: Make sure materials meet the needed standards before starting.

During Production: Look for mistakes early to fix them fast.

Final Check: Confirm the finished harness meets all quality rules before shipping.

Detailed reports are now common in inspections. These reports include dates, locations, inspector names, and even photos of problems. Such records help prove quality and build trust with customers.

証拠の種類 | 説明 |

|---|---|

Finds changes in crimp quality to avoid defects. | |

Customer demand for quality proof | Shows customers want proof of reliable and tested products. |

Statistical reporting | Gives detailed data like averages and defect rates. |

Running electrical and functional tests

Testing checks if the wire harness works as it should. Electrical and functional tests make sure the product is safe and matches its design. This step finds problems like bad parts or assembly mistakes.

Important tests include:

Continuity Testing: Checks for open circuits or shorts.

Insulation Resistance Testing: Makes sure insulation is strong enough.

Dielectric Voltage Withstand Test: Tests insulation against high voltages.

Functional Testing: Connects the harness to a system to check performance.

Automation has made testing faster and more accurate. Machines reduce human mistakes and check more connections quickly. 例えば, automated continuity testers can test hundreds of wires at once. This saves time, lowers costs, and improves quality by catching problems early.

Problem Detection: Finds bad parts or assembly errors.

Performance Check: Ensures the harness works as designed.

コスト削減: Fixes issues early to avoid expensive recalls.

Following industry rules

Following rules is a must in wire harness production. It ensures products are safe, high-quality, and meet global standards. Certifications like ISO 9001 and GMP help maintain consistent quality.

Purpose | |

|---|---|

Visual Inspection | Look for visible issues like loose wires or damage. |

Continuity Testing | Ensure no open circuits or shorts exist. |

Insulation Resistance Testing | Check insulation strength between wires. |

Dielectric Voltage Withstand Test | Test insulation under high voltage. |

Connector and Terminal Testing | Make sure connections are secure and crimped properly. |

Short-Circuit Testing | Test how the harness handles short circuits. |

Resistance and Voltage Drop Testing | Measure resistance and voltage drop under load. |

環境試験 | Simulate real-world conditions to find weak spots. |

Functional Testing | Connect the harness to a system to check all parts work. |

By following these rules, manufacturers meet regulations and gain customer trust. Products with proven quality stand out in the market, helping businesses succeed.

Packaging and Transport in Wire Harness & Cable Assembly Manufacturing

Packaging and transport are important to keep wire harnesses safe. They ensure products arrive in good condition. Proper organization, labeling, and protection help maintain quality. These steps also make it easier to track items during shipping.

Getting products ready for shipping

Organizing products well helps with smooth delivery. Follow these steps to make shipping easier: plan, manage inventory, and fulfill orders. Planning decides what to send, where, and when. Good inventory management avoids running out of stock. Order fulfillment ensures items are packed and shipped quickly.

Here’s a table showing key logistics steps:

Logistics Steps | 何をするのか |

|---|---|

Planning | Decides what, where, and when to deliver. |

Choosing Transportation | Picks the best transport based on cost and speed. |

Inventory Management | Keeps track of stock to avoid delays. |

Warehousing | Organizes storage for faster packing and shipping. |

Order Fulfillment | Packs and ships items quickly and correctly. |

Tracking and Delivery | Monitors shipments to prevent delays. |

Feedback and Improvement | Uses feedback to make shipping better. |

By following these steps, products can be delivered on time and safely.

Labeling and tracking for easy identification

Labels and documents help track products during shipping. Programs like UL Solutions’ Traceability Program assign unique labels to each product. These labels help monitor items from start to finish. Over 2,000 certified manufacturers use this system to ensure quality.

With clear labels, problems can be fixed faster. This reduces delays and keeps customers happy. Traceability also proves that products meet industry rules.

Keeping products safe during transport

Good packaging protects wire harnesses from damage. The type of packaging depends on the product’s size and shape. Strong materials like foam or custom boxes can prevent impacts. This reduces the chance of returns or repairs.

Choosing the right transport method is also important. Think about cost, speed, and shipment type. Real-time tracking systems help monitor deliveries and fix delays quickly. These steps ensure products reach customers safely and on time.

Making wire harnesses and cable assemblies takes many careful steps. Each part, from planning to shipping, is important for good results. Checking quality ensures the harnesses are safe and meet rules.

As electrical systems get more advanced, accuracy matters even more. Special tools like cameras and testers find problems early. Final checks make sure products are safe and follow rules.

Important Industry Facts:

High standards reduce mistakes, especially in big vehicles like trucks.

Full inspections keep defect rates low to meet strict rules.

Special tests confirm all parts are put together correctly.

Wire harnesses are crucial in cars, planes, and hospitals. They help modern machines work smoothly, making them very important today.

よくある質問

What are cable harnesses used for?

Cable harnesses keep wires neat and safe in electrical systems. They are used in cars, planes, and medical machines. These harnesses stop wires from getting damaged by heat or moisture.

How do manufacturers ensure cable harnesses meet quality standards?

Manufacturers check cable harnesses for safety and performance. They follow strict rules like UL and ISO certifications. These tests make sure the harnesses work well in tough conditions.

Can cable harnesses be customized for specific applications?

はい, cable harnesses can be made to fit your needs. Manufacturers adjust wire length, connector type, and other features. Custom harnesses work perfectly with your system.

Why is automation important in cable harness production?

Automation makes production faster and more accurate. Machines cut, strip, and test wires better than people can. This lowers mistakes and keeps quality high for big projects.

How do cable harnesses contribute to safety in vehicles?

Cable harnesses stop electrical problems and keep wires secure. They protect wires from damage caused by heat or shaking. This helps vehicles stay safe and work properly.